-

Article

-

Channel

-

Region

-

Season

-

Tag

Articles

-

Video article 6:48

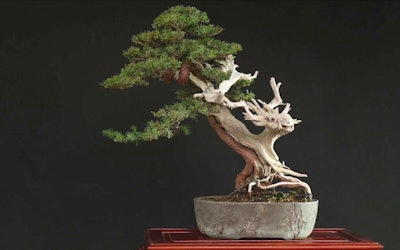

Video article 6:48The skill of the bonsai master of "Kisshoen" in Toyota City, Aichi Prefecture! The world of craftsmanship is shown in this video! See the art of fusion of the natural beauty of materials and human skill!

Traditional Crafts- 235 plays

- YouTube

Japanese Traditional Craft "Bonsai" - Video Introduction of Interview with Bonsai Master in Toyota City, Aichi Prefecture This video "Bonsai"(盆栽) was created by "Nippon Teshigotozukan". It is a video introducing the world of Bonsai featuring an interview with a Bonsai craftsman. Bonsai is the traditional Japanese art of growing miniature trees in containers which are often decorated with moss and other small decorations. Experts in the craft of making Bonsai are called Bonsai masters. The origin of Bonsai dates back to the Heian period (794 - 1185 AD). Bonsai is so popular that the Japanese word 'Bonsai' is known in many countries across the world. In this interview video, you can learn how to create and look after your own Bonsai tree. Please enjoy learning about traditional Japanese culture through this video! What is Bonsai? Let us introduce some of the special techniques required to make Bonsai! Source :YouTube screenshot In this video, we introduce the Bonsai master Okamoto Yoshimitsu, whose workshop "Kichishouen" is located in Toyota city, Aichi prefecture in the Tokai region of Japan. Okamoto Yoshimitsu is famous for his Needle Juniper Bonsai works of art. Source :YouTube screenshot Many techniques are required to complete a Bonsai piece of art, such as pruning, using wires to create bends in the tree's structure and applying paint to name a few. You can see some of these techniques from 2:07 in the video. You can also see some of the tools required for the maintenance of Bonsai from 0:23. Bonsai require special care as the seasons change, similar to other trees in nature. You can see the difference pruning makes to the Bonsai from the before and after pictures at 3:30 in the video. Interview With a Bonsai Master Source :YouTube screenshot From 3:40 in the video, Bonsai master Okamoto Yoshimitsu talks of how he feels the effort put into taking care of Bonsai can be very rewarding, similar to bringing up children. "Bonsai is a Japanese tradition, one that I do not want to die out I want young people to learn about Bonsai and understand the concept of Wabi-sabi (wabi-sabi is a Japanese term used to express the beauty of imperfection). Bonsai is a great way to express oneself through one's own style". Enjoy Looking the Fabulous Bonsai Works of Art Photo:Bonsai Tree Many people in Japan take up Bonsai as a hobby to enjoy the wabi-sabi aspect of the art. There are many varieties of Bonsai tree, from the inexpensive trees aimed at beginners to the very old trees and expensive pots used by professionals and experienced practitioners. The same type of tree, such as a Japanese white pine, can also have several structural forms: formal upright, informal upright, slanted and windswept are a few examples. Other tree types such as cherry blossom and maple trees can also be used. The charm of Bonsai comes from the individualized pruning and shaping of the trees which gives each particular tree it's personality. The combination of the natural beauty of the tree itself and the creativity and individuality of the craftsman is what makes Bonsai so interesting. Bonsai Tree Summary Source :YouTube screenshot Bonsai is a popular Japanese tradition that has been around for many generations. The Bonsai Art Museum in Saitama is growing in popularity, with more young people and foreigners visiting each year. There is also a tapioca shop which serves Bonsai Tapioca Milk Tea which is very popular with customers. Bonsai may look difficult but there are Bonsai for sale that are easy to look after, even for complete beginners. For those who are interested in the traditional Japanese art of Bonsai, why not try raising your own? ◆Kichishouen Introduction Information◆ 【Address】Yabushita 3, Nishimachi, Unebe, Toyota city, Aichi prefecture 470-1219 【Phone number】0565-21-2713 【Official Website】Saitama Bonsai Art Museum https://www.bonsai-art-museum.jp/en/ -

Video article 3:18

Video article 3:18Introducing the charm of Aizu Hongo Pottery, the oldest and most beautiful traditional craft in Tohoku. A work of art created by artisans at the kiln in the town of Aizu Misato, Fukushima Prefecture!

Traditional Crafts- 441 plays

- YouTube

Aizu Misato-cho, Onuma-gun, Fukushima Prefecture "Production of Aizu Hongo Pottery" Video Introduction This video, titled "【会津本郷焼】継承されていく伝統と歴史 /【Aizu Hongouyaki】The tradition and history that are passed down for generations," was created by "Aizu-Hongo Ware Association" (会津本郷焼組合). The video introduces the history and crafting process of the Aizu area's traditional craft, Aizu-hongo Ware. The video is only 3 minutes long, so for those interested in Japanese traditional culture, how pottery is made, or just want to admire some beautiful works of art, definitely check it out! The History of Aizu-Hongo Ware Source :YouTube screenshot Aizu-Hongo Ware originates from the town Aizumisato, near Aizu-Wakamatsu Castle in Fukushima Prefecture in the Tohoku region of Japan. Aizu-Hongo Ware was already being created by the 16th century, leading to it being known as the oldest pottery tradition in Japan's Tohoku region. The pottery pieces are made using high-quality Okubo clay. The clay used for decorating the pieces is also made from materials gathered in the region. This is one of the special characteristics of Aizu-Hongo Ware. Aizu-Hongo Ware is created through traditional methods involving the use of a potter’s wheel, as shown from 1:19 in the video. The high quality and exquisite beauty of the pieces has led to Aizu-Hongo Ware being designated a Traditional Craft of Japan. How To Create Aizu-Hongo Ware Source :YouTube screenshot There are many kilns for making Aizu-Hongo Ware in the Aizu region. The pieces created by the Kamomoto craftsmen are beautiful enough to be called works of art. In the Aizu region, there are many pottery classes and pottery-making experiences available. Through creating Aizu-Hongo Ware, you'll gain a deeper understanding of Japanese culture. Besides visiting the Aizu region itself, you can also purchase pottery pieces online. As shown from 2:26 in the video, there are various types of products that can be used in daily life, such as mugs, bowls, coffee cups, Japanese teacups and more. Be sure to check them out if you're interested. Summary of Aizu-Hongo Ware Source :YouTube screenshot Aizu-Hongo Ware is a deep-rooted tradition of the Aizu region, with a long, rich history. If you have the chance to visit Aizumisato, not only can you learn more about this traditional craft, but you can also view the beautiful Japanese landscapes of the region. Immerse yourself in Japanese culture through Aizu-Hongo Ware! -

Video article 4:56

Video article 4:56Grand Seiko's Spring Drive is packed with world-class technology and the passion of its developers. A watch craftsman in Shiojiri, Nagano Prefecture, talks about his precision and high-precision handiwork!

Life & Business- 88 plays

- YouTube

Grand Seiko, Nagano, Japan - Watchmaker Video Introduction This video is "Inside Grand Seiko, Episode One: The Master Craftsman" produced by "Hodinkee". It is a valuable video that shows us the state and production process of the workshop that makes the world-class precision watches "Grand Seiko." The commitment of these Watchmaker's cannot be overlooked! The Japanese Micro-Artist Studio Behind Grand Seiko Watches Source :YouTube screenshot Seiko Epson's Shiojiri office in the Koshinetsu region and the Suwa region of Nagano prefecture, introduced in this video, was established with the aim of inheriting the techniques of the watchmaker "Micro Artist Studio." "Every one must be beautiful," says watchmaker Yoshifusa Nakazawa, a watch assembler who continues to produce watches in this studio (0:50 in the video). Mr. Nakazawa has been active as a watch assembler since joining the company in 1978, and in 1981 won the World Skills Competition in Japan. In this workshop, the assembly of the movement (the part that controls the driving of the wristwatch), the installation of the dial, and the case insertion are all performed consistently, so that steps such as maintenance and overhaul can be easily performed. From 1:06 of the video, you can see how precisely each watch is assembled, sometimes using a microscope. From 3:23 in the video, he says, "Mr. Nakazawa inherits 100% of the technology of assembling watches, and the best watches are assembled neatly." What Is Grand Seiko's Original Mechanism the "Spring Drive"!? Source :YouTube screenshot The mechanism “spring drive” mounted on Grand Seiko, which can be seen from 2:51 in the video, is said to be a third engine that combines machinery and quartz. It has a history of 20 years as a model symbolizing the Grand Seiko brand. The model called "44GS" established the design of Seiko style in 1967. It lists three policies, which are as follows: 1. Design consisting of a plane and quadratic surface, with a plane as the main body. Cubic surfaces are not used in principle. 2. Increase the area of the flat surface as much as possible over all cases, dials and hands. 3. In principle, each surface is a mirror surface, and distortion from each mirror surface is minimized as much as possible. Based on this policy, the 44GS was designed with nine features. This Seiko style is designed to spice up the beauty of Japan. It considers the "light" of Japanese people, and those who hold it can feel the beauty of the Japanese in its undistorted, flat planes. Grand Seiko can be called a work packed with the aesthetic sense of Japan. Master Shops Where You Can Buy Limited Items From Grand Seiko Photo:SEIKO The Grand Seiko Master Shops refer to about 140 shops in Japan that have signed a contract with Seiko, and there are several types of limited models sold only to that master shop. Not only men models, but valuable diver models and ladies' models are popular as well. For a list of watches, see the official website. In addition, you can apply for battery replacement from the official website, so please check it out. Of course, Grand Seiko can also be purchased online. Summary of the Popular Japanese Watch Grand Seiko Source :YouTube screenshot Japan's proud Grand Seiko watches have a high reputation in Japan and around the world as watches with a history and ideology. At the end of the video, Nakazawa says, "I imagine that those who use Grand Seiko watches will hand them over to the next generation and pass them on." Why not get your own watch? One that has been created as a work of art that inherits Japanese technology. 【Official Website】Grand Seiko Official Site https://www.grand-seiko.com/us-en -

Video article 2:11

Video article 2:11Carry Japanese culture with you! Original iPhone case made by a maki-e artist in Wajima City, Ishikawa Prefecture, Japan! Watch the video of the work process!

Traditional Crafts- 138 plays

- YouTube

Video introduction of the maki-e process of a maki-e artist in Wajima City, Ishikawa Prefecture, Japan! What is Makie? This video, titled "Maki-e Time Lapse ART iPhone 6 Case "Zelkova," Lacquer Application, Wajima Lacquer, Maki-e, Goldfish, How to" (Maki-e time lapse ART iphone6ケース「欅」拭き漆 輪島 蒔絵 金魚 工程 A process), was released by "no to char." It's a promotional video that shows Japan's traditional Maki-e lacquerware process in a timelapse. The video shows how Mitsuru Yamashita, a lacquer artist from Wajima City, Ishikawa, who is famous for producing lacquer, paints a beautiful goldfish on an iPhone case made of zelkova. It looks real enough to swim away! Maki-e, a traditional Japanese craft, is a lacquerware technique, that has been handed down since ancient times in Japan. It's a decorative technique that involves drawing a pattern on lacquerware or wood with lacquer or applying metal powder such as gold, silver, and tin on it before it dries. Lacquer is a natural paint made from the resin of plants of the Anacardiaceae family and has a culture and history of being used in architecture, furniture, stationery, etc. in Japan. Lacquered products are manufactured by division of labor, and the craftsmen who apply the decorative Maki-e designs are called "Maki-e-shi" (蒔絵師). In this video, you can see the techniques of the lacquer artist and the time and process required to make the Maki-e goldfish on the iPhone case. In recent years, "Maki-e" products are seen not only as traditional crafts, but products with Maki-e on ballpoint pens, fountain pens, accessories, stickers, etc. have become common as well. These are objects that can be used daily in modern life and are a way to implement a part of Japanese culture and traditional Japanese crafts into your everyday life. Maki-e, A Traditional Japanese Craft: How It's Made Source :YouTube screenshot In this video, they begin by designing the goldfish, which can be seen from 0:07 in the video, then copying the sketch called an "Okime" on the zelkova iPhone case, applying lacquer with a Maki-e brush, and then sprinkling it with metal powder and then drying it. At the end, they apply "fuki urushi" (wiping lacquer) to the zelkova iPhone case in order to finish it with a beautiful glossy transparent wood grain. You can see the beautiful shining Maki-e design and the finished product, from 1:54 in the video. The finished lacquer gives off a beautiful luster, and you can experience the beauty of traditional Japanese Maki-e and the magnificence of handicrafts in Japanese culture. Maki-e is categorized into several types depending on the process used, including "Hira Maki-e," "Togidashi Maki-e," "Taka Maki-e," and "Shishiai Maki-e." The technique that is seen in the video is "Taka Maki-e" and the lacquer is raised to draw a pattern and express it in a relief shape. The goldfish that rises smoothly from the wood is three-dimensionally expressed by the unevenness of the lacquer, and it is characterized by the deep color of the lacquer that has been applied many times. Summary of Maki-e, A Traditional Craft That Conveys Japanese Culture Source :YouTube screenshot Maki-e is said to have originated in the Heian period (794-1185), and it is an aspect of Japanese culture and traditional crafts with a long history. There are also national treasures that have been made using Maki-e techniques, and it is one traditional craft that should be protected as a traditional technique that conveys Japanese culture. Videos like this, where we can learn about traditional Maki-e techniques and how to use them, are important in passing down the traditional craft to future generations so they may cherish it like their ancestors did before them. -

Video article 5:00

Video article 5:00Uetsu Shinafu: A Traditional Craft of Yamagata Prefecture with Which You Can Feel the Beauty of Ancient Japanese Culture. Don’t Overlook These Exquisite Woven Works of Art That Remind Us of Days Past

Traditional Crafts- 172 plays

- YouTube

Check out This Video Introducing Uetsu Shinafu, a Traditional Japanese Crafts! This video, titled "Handmade Crafts "Uetsu Shinafu Weaving" / Japan Traditional Crafts Aoyama Square," introduces uetsu shinafu. The video was uploaded by Traditional Crafts Aoyama Square. Uetsu shinafu fabric is the oldest fabric in Japan woven using tree bark fibers. They were first created during the Jomon period (14,000 BC to 400 BC), and are counted as one of Japan's Three Ancient Woven Fabrics. Today, uetsu shinafu is produced in Tsuruoka, Yamagata Prefecture, the Sekigawa District of Uzen, as well as Murakami, Niigata Prefecture. In 2005, these uetsu shinafu products were designated Traditional Crafts by the Ministry of Economy, Trade and Information. In this video, the production process of uetsu shinafu is introduced in detail. Do enjoy this video showing a tradition of Japan from days past. What Is Uetsu Shinafu? Introducing the Production Process and Methods Used to Make Them Source :YouTube screenshot The raw material of uetsu shinafu is bark derived from the Japanese Linden Tree, as shown from 0:33 in the video, with other sources being the bark of the, tilia maximowicziana, as well as the tilia noziricola. Firstly, the bark is peeled and dried, then boiled in water containing wood ash. Next, as shown in the video, the fibers are scrubbed in a river then dried once more. Following that, the fibers are shredded by hand into thin threads in a process called shinasaki. These threads are then joined to form one long thread in a process called shinaumi. Then, the threads are twisted into a spool and called shinayori . The skill of the craftsman is critical in this entire process, as it is all done by hand. Lastly, the threads are placed on a platform known as the uttate, and the threads are then reeled (3:26). Finally, the threads are woven into a piece of fabric. Where Can You Purchase Uetsu Shinafu Products? Source :YouTube screenshot From 4:19 in the video, works created using uetsu shinafu fabric are introduced. Different kinds of bags, decorative items such as tapestries, name card holders, wallets, obi sashes, hats, fabric dividers – there is a wide variety of products. Besides tourist areas in Yamagata Prefecture, uetsu shinafu products can also be purchased through mail order. As for those who would like to try their hand at uetsu shinafu, the Uetsu Shinafu Promotion Council (振興協議会), the Shinaori Center (織センター), or Sekigawa Shinaori Village (関川しな織の里ぬくもり館) are all places you can visit. Summary of Uetsu Shinafu Source :YouTube screenshot Uetsu shinafu: exquisite works of art with a pleasant texture. Isn’t it unbelievable that its origins date back to the Jomon period thousands of years ago? As shown in the video, uetsu shinafu fabric is created through a complicated process, with the craftsmen ensuring that every single step is done to the best of their ability. Thus, uetsu shinafu products can be used for a long time. If this video has you interested in uetsu shinafu, do take the opportunity to purchase an uetsu shinafu product or try an uetsu shinafu experience in Japan! 【Official Website】Uetsu Shinafu Promotion Council Yamagata Prefecture-Tsuruoka City・Niigata Prefecture-Murakami City, Ancient Fabrics Village http://shinafu.jp/ -

Video article 4:51

Video article 4:51A Look at Japan's Highly Sophisticated Coinage! Rare Footage Showing the Latest Japanese Coinage Technology Acknowledged Around the World!

Life & Business- 52 plays

- YouTube

A Look at Japan's Currency Manufacturing Technology This video, titled "Japanese Currency Manufacturing Technology" (日本の貨幣製造技術), was released by "Japan Video Topics - 日本語". Japanese currency is created in accordance with the "Acts on Currency Units and Issuance of Coinage" (通貨の単位及び貨幣の発行等に関する法律). Currently, 6 types of coins and 4 types of banknotes issued by the Bank of Japan are in circulation, and 3 billion banknotes are printed every year. The History and Unique Characteristics of Japanese Currency Source :YouTube screenshot Today's Japanese banknotes are made through a method in which design and engraving specialists create the original designs with a brush, design a copper plate similar to a woodblock print and it is then printed by the National Printing Bureau. You can see the production process of these banknotes from 0:48 in the video. Throughout the long history of Japan, such as the Showa and Heisei periods, coinage technology of has dramatically improved. The value of Japanese coin manufacturing technology is recognized around the world, and in recent years, coin manufacturing has become a typical Japanese culture, with some people being asked to manufacture foreign coins as well. The Unique Ingenuity Incorporated Into Japanese Currency Source :YouTube screenshot Japanese banknotes and silver coins are actually packed with many innovations that bring together the advanced technology of traditional Japanese manufacturing. For example, Japanese bills have a watermark that makes a portrait appear when held over light. Ink is used for banknotes to create bumps when printing, so even blind people can touch the banknote and know what type it is. In addition, advanced anti-counterfeiting technology is used for Japanese floral patterns, such as the use of "Bank of Japan" micro-lettering, which cannot be color-copied, and "diagonal jaggedness" on the sides of the coins. Other advanced technologies such as "latent imaging," "fine lining," and "fine dotting," are also used in Japanese currency manufacturing. This amazing technology has been praised around the world for its ability to check the latent images and holograms of the 10,000-yen bill and the portraits and vertical bars of the 1,000-yen bill by touching, tilting, or holding them up to light. Summary of Japan's Currency Manufacturing Photo:Japanese money Japan's coinage is not something that can be seen often, so be sure to check it out if you still haven't yet! In Japan, the notes are scheduled to change in 2024, so keep an eye out for the new designs! In addition, commemorative coins are likely to be issued at events, such as the Olympics, so be sure to get one if you visit! -

Video article 14:51

Video article 14:51Kakejiku - Traditional Japanese Hanging Scroll Art

Traditional Crafts Art & Architecture History- 335 plays

- YouTube

An Introduction to "Kakejiku" This video titled “Kakejiku-Making of a Japanese Hanging Scroll “ produced by “Niko Kitsakis” features how to make a kakejiku by Koseido Kamon Hyoguten. Koseido Kamon Hyoguten in Takarazuka city (宝塚市:Takarazuka-shi ), Hyogo (兵庫県: Hyogo prefecture) was established in 1912. Hideyuki Kamon is the fourth hyogushi (mounter) of this store. Hyogu refers to scrolls, hanging scrolls, folding screens, fusuma (sliding doors), panels, frames, and picture books made by stretching cloth and paper. Hideyuki Kamon, a first class mounting technician, is involved in various works including the making of kakejiku, frames, folding screens, partitions, and the repairing of shoji or old calligraphic works. This video focuses on the making of kakejiku (a very rare sight), as well as the names of the scrolls. Please enjoy the video of this ancient Japanese craft. The Origin and Culture of Kakejiku Photo:Kakejiku People enjoy having kakejiku displayed in their living room. Kakejiku is also called Kakehaba or Yukakake. The art originated in China and came to Japan along with Buddhism over 1000 years ago, before the Heian Period. Its style was established through the cultures of Calligraphy and Tea Ceremony. https://en.wikipedia.org/wiki/Heian_period In this video, Hideyuki Kamon talks about the history of Kakejiku from the Kamakura, Edo period to now. There are various types of kakejiku such as Kakemono or Kakeji and Buddhist sutra, ink painting or calligraphy, as well as modern illustrations are drawn in a kakejiku. Kakehaba is counted as “Hito-haba, Futa-haba”. Hideyuki Kamon, the Mounter Who Keeps Pushing Himself Source :YouTube screenshot Hideyuki Kamon says Kakejiku is very deep and he is always finding new ways to challenge himself. According to the interview with him, he discovers new things every day and works hard to refine his new discoveries. How to Make Kakejiku Source :YouTube screenshot You can see how kakejiku are made in the footage from 6:14. Kakejiku is made of washi (traditional Japanese handmade paper), cloth and wooden sticks. A Kakejiku consists of components such as Honshi, Futai, Ichimonji, Chumawashi, Hashira and Hasso. The top and bottom parts of a kakejiku are called "Ten" and "Chi," respectively. The mounter’s techniques are necessary to decorate the washi. You can see a Honshi being sharpened by Ichimonji in the footage from 6:37. A kakejiku is completed through these various steps. Get a Beautiful Kakejiku and Feel Traditional Japanese Culture in Your Own Home! Prices for historical works or ones made by famous artists could end up costing you a lot of money. On the other hand, you can buy kakejiku online at sites like Amazon or Rakuten. If you are interested in ink painting or calligraphy or want to incorporate some Japanese culture into your life, we recommend getting a handmade kakejiku. It's important to focus on not only design, size, and characteristics of the kakejiku, but also on a preservation or storing method for the works before purchasing them. Summary of Kakejiku Kakejiku is a high quality, traditional Japanese craft. Please watch the impressive skills of this kakejiku artisan to learn how to make beautiful kakejiku. Enter the world of kakejiku that you didn’t even know existed. 【Official Website】Koseido Kamon Hyoguten in Takarazuka- A shop to first class mounters https://kouseidou.jp/ -

Video article 4:34

Video article 4:34Edo Furin (Wind Chimes) Have Been Used in Japan for Hundreds of Years as a Way To Feel Cool and Refreshed in the Heat of Summer. Find Out Exactly How They're Made in This Article!

Traditional Culture Traditional Crafts- 205 plays

- YouTube

An Introduction to Edo Furin Wind Chimes This video, titled "Edo Furin – Let the sound of the wind chimes refresh you" (江戸風鈴~音色で涼しさを感じる~), was created by "Japan Video Topics." It's an introductory video showcasing the traditional Japanese glass wind chimes "Edo Furin" (江戸風鈴). This video answers the following questions: ・What are "Furin" (Japanese wind chimes)? ・What are the origins of "Furin"? ・How are Edo Furin made? Back when there was no air conditioning in Japan, people thought of many ways to feel cool and refreshed in the heat of summer. Bamboo screens called "sudare" were used to block out the sunlight and water was sprinkled on the ground to cool down the pavement outside of one's home. Furin were another item created to help deal with the summer heat. Wind chimes are often hung from the eaves of one's home, and when the wind blows they create a beautiful melody that makes you feel cool and refreshed. This article and video will introduce "Edo Furin," a type of Japanese wind chime made of glass. Be sure to watch the video to learn more about what exactly Edo Furin are and how they're made. What are "Edo Furin"? Photo:Japanese traditional craft Edo Furin Edo Furin are made today using the same techniques that were used 300 years ago (during the Edo period (1603AD - 1868AD)). Furin (wind chimes) date all the way back to the 7th century in Japan. They were often hung from the eaves of temples and were at the time referred to as "Futaku" (風鐸). Futaku were made of metal and were believed to prevent natural disasters. Nowadays, Furin are available in a variety of shapes and colors. In 1965, Yoshiharu Shinohara (篠原儀治) came up with the name "Edo Furin" for the glass Furin he had been taught to make from previous generations. The glass Furin, which are made completely by hand and without using any sort of mold, are known for the characteristic sound they produce. The Process of Making Edo Furin: Photo:How Edo Furin, a traditional Japanese craft, are made First, glass is melted inside a crucible in a furnace. 1. The melted glass is wrapped around a glass rod. 2. A glass sphere is created by blowing into a tube. 3. Additional melted glass is wrapped around the first sphere. 4. A hole is created to pass a thread through. 5. After blowing a second larger glass sphere, the two spheres are separated by cutting off the first smaller sphere. 6. The edges are smoothed slightly, purposefully leaving a rough, jagged edge. 7. Finally, the glass sphere is hand painted from the inside. From 2:00 in the video, you can take a look at Kenichi Otsuki (大槻賢一) (a craftsman of Shinohara Furin Honpo (篠原風鈴本舗)) as he creates Edo Furin by hand. More About "Edo Furin," a Traditional Japanese Craft Photo:Edo Furin, a traditional Japanese craft One of the striking features of Edo Furin is the sound created by the jagged glass edge, which is similar to the sound of a bell cricket in fall. "Shinohara Furin Honpo," the Edo Furin store introduced in the video, is located in Asakusa, Edogawa, Tokyo (東京都江戸川区浅草) and currently sells a variety of Edo Furin as well as offering glassblowing experiences and Edo Furin decorating experiences. Edo Furin can also be purchased online with prices starting at around ¥1,870. More expensive items include the Edokiriko Edo Furin which costs ¥6,050, the checkered pattern Edo Furin which costs ¥11,000 and the unique Temari design Edo Furin can be purchased for ¥44,000. (Prices correct as of December 2020) Summary of "Edo Furin," a Traditional Japanese Craft Photo:The traditional Japanese craft Edo Furin and a Woman in Yukata One of the most fascinating features of Edo Furin is the fact that each and every one has a unique sound as a result of the traditional method used to make them, a method which has been passed down through generations for hundreds of years. In the video, you can learn about the history and unique characteristics of Edo Furin as well as how they're made! -

Video article 10:50

Video article 10:50Showcasing the Brilliant Knife Work of the Chef! A Sushi Chef Creates a Masterpiece of Tuna, the Epitome of Japanese Cuisine, With Masterful Craftsmanship!

Food & Drink- 166 plays

- YouTube

板前の華麗な包丁さばきをご覧になれる動画について こちらの動画は「寿司マスターToshi」が公開した「寿司職人によるマグロの仕込みから握りまで〜How To Make Tuna Sushi〜」です。 日本人に親しみが深い、寿司。 マグロやブリといった新鮮な魚介類や海鮮食材を材料として使用して作られる握り寿司は、和食の代表格です。 近年では海外でも人気が高まっており、現地のスーパーでも見かけることが多くなってきました。 そんな寿司は職人がマグロを捌く処理部分から仕込みをしていることをご存知でしょうか? 今回は職人が仕込みから行う和食・海鮮料理の代表格、マグロの握り寿司について紹介いたします。 職人が1から仕込みを担当、マグロの寿司 寿司に使用されるマグロを始めとした寿司ネタ。 釣り上げられたマグロは解体され、板前さんのところに運ばれてきます。 そして部位ごとに捌くことに。 その手際は素晴らしいもので、動画でもご覧になれます。 熟練の職人技で磨き上げられた包丁捌きで大トロ、中トロ、赤身と捌くその姿はまさに職人。 ネタは部位ごとに切り分けられ、様々な料理へと使用されて行きます。 その手際の良さは和食・日本料理の魅力を再確認させてくれるほどです。 寿司以外にもたくさん!和食に欠かせないマグロ 寿司以外にもマグロを食材として調理された和食料理はたくさんあります。 代表的な握り寿司から、マグロや旬のネタの刺身を芸術作品のように見立てたお造り、マグロを保存が効くように加工し漬けたマグロ漬け丼など、どれも製法に工夫が見られるものばかり。 数え始めたらキリがありません。 日本料理にはマグロを始めとした、新鮮な魚介類や食材を使用した海鮮料理が多く存在しています。 海に囲まれた日本ならではの食文化で、和食と呼ぶに相応しいです。 寿司職人や日本料理のプロが仕込みから行う、マグロを使用した和食。 どの和食も日本を訪れた際に、必ず食べたい一品です。 板前の華麗な包丁さばき動画紹介まとめ 今回は和食の代表格、寿司をはじめとしたマグロ料理について紹介しました。 マグロの刺身やお造りなどの和食料理の数々は、日本料理の代表といっても過言ではありませんね。 板前さんによる職人技が光る仕込みの様子を見たいという方は、是非この動画をチェックしてみましょう! -

Video article 9:47

Video article 9:47These Beautiful Lacquered Vessels Are Works of Art That Enhance the Flavors of Japanese Cuisine. One Woman Shares Her Thoughts on the Traditional Japanese Craft After 30 Years of Fascination

Traditional Crafts- 107 plays

- YouTube

Introducing Traditional Japanese Lacquerware and Japanese Food Culture This video, titled “URUSHI - IS JAPAN COOL? WASHOKU - 和食 (漆芸),” was released by ANA Global Channel. It introduces urushi-e (lacquerware), a traditional Japanese craft, along with amazing arrangements of traditional Japanese cuisine. There are many highly skilled lacquer craftsmen in Japan, and some of them have even been designated as living national treasures (holders of important intangible cultural assets). Japanese ryotei (Japanese-style restaurants) and ryokan (Japanese-style inns) serve Japanese food on lacquered dishes so that guests can enjoy their meals both visually and with regards to flavor. As shown at 6:08 in the video, serving Japanese food on beautiful lacquerware not only looks good, but also helps one enjoy the food. The lacquerware craftswoman featured in the video is a foreign woman who moved to Wajima, famous for its lacquerware, to study the traditional Japanese craft. You can see her passion for Japanese lacquerware as well as a close look at how she makes them. The History and Culture of Lacquerware, a Traditional Japanese Craft Photo:Lacquerware The history of traditional Japanese lacquerware dates back 9,000 years, with lacquered vessels excavated from Jomon Period (14,000 BC to 400 BC) ruins. Lacquer was used to bond and decorate earthenware during the Jomon and Yayoi (ca. 300 B.C. to 250 A.D.) Periods, and since then it has been used for many other purposes, such as vessels and wooden products. In Japan, there are many areas where lacquer is produced as a specialty product. Two examples of this include Wajima-nuri (輪島塗) and Tsugaru-nuri (津軽塗). In Ishikawa Prefecture in particular, there's the Wajima Museum of Lacquer (Urushi) Art that introduces the Japanese culture and production process of Wajima-nuri. A Closer Look at Japan’s Traditional Lacquerware Photo:Lacquerware There are many different types of lacquerware, such as Rantai Shikki (籃胎漆器, lacquerware that uses woven bamboo baskets as a base), Kanshitsu (乾漆, a dry lacquerware technique introduced from Tang China in the Nara Period), and Kinma (蒟醤, lacquerware carved with a blade). Lacquerware is decorated using a variety of techniques, such as maki-e (蒔絵, lacquerware using gold or silver powder), raden (螺鈿, mother-of-pearl inlay), chinking (沈金), hyomon (平文), and more. There are also techniques such as decoration using eggshells, lacquer paintings, Kamakura-bori (鎌倉彫), and engraving. In recent years, lacquerware techniques have been used not only for vessels but also for tools, such as combs, and stationery, such as ballpoint pens. From 8:27 in the video, you can see some lacquerware earrings and other accessories. Summary of Japan’s Traditional Craft - Lacquerware Photo:Lacquerware As shown in the video, there are many beautiful vessels made in Japan that look like works of art. If you want to experience traditional Japanese lacquerware crafting in person, we recommend checking out a class or school certified by the Society for the Preservation of Traditional Japanese Lacquer (漆芸伝承の会認定). Lacquerware features a wide range of products, from those produced by famous artists to more affordable pieces. We recommend purchasing lacquerware from one of the famous lacquerware producing regions of Japan, so that you too can enjoy delicious Japanese cuisine even more! -

Video article 6:41

Video article 6:41Enjoy Watching How the Traditional Sweet "Dragon's Beard Candy," a Popular Delicacy in China and Korea, Is Made in This Amazing Demonstration Video! The Delicate Sweets Created by the Cheery Professional in This Video Are Simply Amazing!

Food & Drink Shopping- 2.41K plays

- YouTube

About the Demonstrational "Dragon Beard's Candy" Video This video features footage of a professional making traditional dragon beard's candy by hand at a food stall in the Shin-Okubo area of Shinjuku, Tokyo (東京都新宿の新大久保). The delicate sweets, which are known for being difficult to make, are a traditional sweet in Korea which are also known by the name Kkul-tarae (クルタレ) or Ronshutan (ロンシュータン). In this video, you can see the techniques used to make dragon's beard candy and learn more about the history and characteristics of this traditional sweet. We hope you enjoy the video! What Is Dragon's Beard Candy? Source :YouTube screenshot Dragon's beard candy is a traditional sweet which has been eaten in countries such as China, Korea and Taiwan for hundreds of years. Its popularity has spread to other foreign countries, such as the US, Taiwan, Singapore, Canada and Hong Kong. Dragon beard's candy originated in China over 2,000 years ago, when the delicate treat was originally prepared for the emperor; however, it eventually came to be eaten by ordinary citizens and has been loved to this day. The main ingredient used to make dragon beard's candy is maltose syrup, known as "mugi mizuame" in Japanese. Cornstarch is also an essential ingredient. It's made by stretching a hard piece of candy over and over again to create a candy with a light and crunchy texture. The mildly sweet Dragon's beard candy is often given as a gift (lucky charm) in Seoul, Korea. Watch the Amazing Skills of This Professional Dragon Beard's Candy Maker in Shin-Okubo! Source :YouTube screenshot Each piece of dragon's beard candy is carefully handmade by craftsmen. As can be seen in the video, the street vendor first prepares the maltose syrup candy. He creates a hole in the hard candy and proceeds to stretch the candy using this hole. You can take a look at the stretching process throughout the video. The vendor then stretches the candy over and over while continually covering it in cornstarch until the threads of the candy reach the thickness of what is thought to resemble a dragon's beard. Only highly skilled professionals can make the candy incredibly thin without it breaking or snapping. A single piece of candy is stretched into an amazing 16,384 strands. From 4:26 in the video, the street vendor explains that this is the perfect number of strands to create the most pleasant melt-in-your-mouth texture. At 2:20 in the video, he begins to fold the candy to create the 16,384 strands, which he completes in roughly 35-40 seconds. The highlight of the video has to be when the professional dragon's beard maker shows off the finished product to the customers, at which point it looks beautifully smooth like threads of silk. Many customers are amazed by the look of the finished product! You can take a look at this in the video at 4:18. If you get a chance to see it up close, be sure to take a video of your own and share it with your friends! Source :YouTube screenshot After stretching out the candy, crushed peanuts, almonds, sesame seeds, or coconut can be added as a filling. One piece of candy costs approximately a few hundred yen (a couple bucks (USD)). There are very few people who know how to make the candy as the skills required are so difficult to master. Summary of Dragon Beard Candy There are food stalls in Shin-Okubo and Yokohama's Chinatown (横浜中華街, yokohamachuukagai) where you can watch dragon beard's candy being made right before your eyes. You can also buy dragon beard's candy online, sometimes sold under the name "Dragon Candy." For those interested in tasting and experiencing the delicate texture of dragon beard's candy, we highly recommended purchasing some and trying them out for yourself! Watching how the amazing dragon beard candy is made is guaranteed to pique your curiosity! Be sure to check it out in the video! -

Video article 3:29

Video article 3:29Suruga Bamboo Sen-suji-zaiku, a traditional handicraft, is a true work of art! Watch a video of the amazing skills of craftsmen in Shizuoka City, Shizuoka Prefecture, who create delicate and graceful bamboo works!

Traditional Crafts History Life & Business- 485 plays

- YouTube

Suruga Bamboo Sen-suji-zaiku, a Traditional Craft, Video Introduction of Craftsmanship in Shizuoka City, Shizuoka Prefecture This is a promotional video for Suruga Take Sensuji Zaiku (Suruga Bamboo Ware), created by Aoyama Square, a shop specializing in traditional Japanese crafts. Suruga Bamboo Ware is a traditional craft made from bamboo stems. Created using professional techniques whereby the craftsman creates flower vases, bug cages, and handbags by assembling thin strips cut from bamboo stems. In recent years, it has become popular with more modern items, such as bags and wind chimes. Today, we'll introduce in detail the highly valued traditional Japanese craft, Suruga Bamboo Ware. Be sure to follow along with the video! The History of Suruga Bamboo Ware ©SUN Modifying Due to rich bamboo resources, bamboo crafts were commonly used in daily life from olden times in the Suruga area, in Shizuoka prefecture. The origin of the craft is rooted in ancient history. Bamboo products like baskets and cages have been excavated from Toro ruins in this area, major ruins of the Yayoi period. In the Edo period, bamboo crafts established a position as side jobs for samurai. After retiring from the shogunate, Tokugawa Ieyasu lived in Sunpu Castle, and a local culture of bamboo craftsmen was established in the Suruga area. Suruga Bamboo Ware was recognized as national traditional craft by the Ministry of International Trade and Industry in 1976. How Suruga Bamboo Ware Is Made Source :YouTube screenshot The production process of Suruga Bamboo Ware is divided into 4 parts: Measuring and cutting bamboo, Bending, Weaving, and Assembly. Japanese timber bamboo (Madake) or Moso bamboo (Mosochiku) are used as materials, and strips are cut from their stalks. Flat strips are used for bamboo crafts in other areas, but Suruga Bamboo Ware uses round cut strips. They are made using a unique technique that involves bending the strips into round shapes and connecting them through weaving. The distinctive feature of Suruga Bamboo Ware is that all processes, from the cutting and measuring of bamboo to the finishing touches, are done by a single craftsman. A more detailed process is shown in the video at 0:25. Please enjoy the techniques of Suruga Bamboo Ware craftsman, Takahide Sugiyama. Suruga Bamboo Ware Products Source :YouTube screenshot There are many different Suruga Bamboo Ware products; snack trays, which are great for hosting guests, flower vases, tea cup saucers, small pouches, lightings such as lanterns and lamps, wind chimes/desktop wind bells, bug cages, and more. Beautiful Japanese style handbags are also popular. These products can be purchased on amazon and Japan’s major online retailer, Rakuten. Prices range from several thousands to several tens of thousands of Japanese yen (tens to hundreds of dollars), depending on the product. Summary of Suruga Bamboo Ware As introduced in the video, Suruga Bamboo Ware is traditional Japanese craft handmade by a single artisan. If you're looking to take in some Japanese culture in your daily life, we recommend purchasing some Suruga Bamboo Ware products. They make great souvenirs and gifts as well. 【Official website】Suruga Bamboo Ware "Shizuoka Bamboo-crafts Cooperative" http://www.takesensuji.jp/?mode=f8 【Official website】Japan Traditional Crafts Aoyama Square https://kougeihin.jp/en/ -

Video article 3:49

Video article 3:49What's That Amazing Smell?! The Skill Of These Baby Castella Craftsmen Is Nothing Short Of Amazing! Be Amazed by the Mouth-Watering Performance While You Wait for Your Chance To Buy!

Food & Drink Shopping- 833 plays

- YouTube

Introducing Baby Castella Stalls! "Japanese Stall Series: Baby Castella Edition(日本の屋台シリーズ ベビーカステラ編)" is a video that people who love Japanese festival culture and event stalls should definitely watch. Baby Castella is a standard for festival menus. At the stalls, they use a special baking machine similar to a takoyaki machine and bake round and cute castella with amazing craftsmanship. Check out the amazing skills of real craftsmen at baby castella specialty stores that are especially popular at Japanese food stalls. What Are Baby Castella? Origins and How They're Made Photo:Baby Castella It is said that the history of Baby Castella began in the Taisho era (1912 to 1926 AD) with a stall in Nishinomiya City, Hyogo Prefecture in Japan's Kansai region. A stall craftsman made a menu that closely resembles a commercially available bell castella, and it became a very popular product. You can learn more about how to make baby castella at 0:53 in the video. Just pour the dough into a special baking machine that the craftsman has, close the baking machine lid and bake it. As you can see from 3:34, the baked baby castella uses a skewer to fly neatly into the pom-pom and saucer. It looks easy, but baking a lot of baby castellas requires the quick work of a skilled craftsman. Calories and Prices of Baby Castella Photo:Baby Castella Nakazawa Seika, a famous baby castella store that has opened stores in Fukagawa Fudo and Asakusa Tori-no-ichi, is a castella specialty shop where you can wait for up to three hours. The baby castella sold at the shop is pretty reasonably priced however. They start at 12 for 300 yen (~$3 USD). One baby castella is about 30 calories, but these babies are freshly made and super tasty, so you might want to be careful about eating too much. Making Baby Castella at Home! Photo:Baby castella made with a takoyaki pan It is often thought that a special machine used in a specialty store is needed to make baby castella, but you can actually make them at home, using a takoyaki machine. If you use a hot cake mix and bake the dough with a takoyaki machine, you can make your very own delicious baby castella. We recommend giving it a try if you have the chance! Summary of the Baby Castella Stalls Source :YouTube screenshot There are many people who look forward to eating street food at festivals. On festival and event days, eating lunch and snacks at the stalls is a great way to try new foods and make some great memories. One of the pleasures of Japanese food stalls is to be able to see the craftsman's skills in action. If you are sightseeing in Japan, be sure to stop by the baby castella stalls where you can see the amazing techniques shown in the video. -

Video article 3:42

Video article 3:42Discover the Secrets Behind the Beauty of Bizen Ware, a Ceramic Craft From Okayama Prefecture Handed Down Since the Heian Period! A Craft That Captures the Hearts of Tourists!

Traditional Crafts- 234 plays

- YouTube

Introducing the Beautiful Ceramic Art, Bizen Ware This video, titled "TEWAZA (Handicraft) Bizen Pottery / Japan traditional crafts Aoyama Square" (手技TEWAZA「備前焼」Bizen pottery/伝統工芸 青山スクエア Japan traditional crafts Aoyama Square), was released by "Traditional Crafts Aoyama Square." Bizen Ware is a traditional Japanese craft with a long history and is known as one of the "Six Ancient Kilns of Japan" and well as being known as "Inbe Yaki." Bizen Ware is a traditional pottery that is popular for its solid reddish/brownish color, glassy surface, and rugged texture, which are brought out by its unique unglazed appearance through a method of high-temperature firing via direct contact with the flame. A Closer Look at Okayama's Bizen Ware Photo:Bizen Ware Bizen Ware is made of unique clay obtained from the rice fields in Okayama Prefecture. It is called one of the "Six Ancients Kilns" because it can be found in literature dating back to the Heian period (794-1185 AD). Since then, Bizen Ware has continued to produce tea ware masterpieces and successors are still being trained today. Bizen Ware has long been a prominent part of the culture and industry of Okayama Prefecture, located in Japan's Chugoku Region (中国地方, Chugoku-Chiho), and is a representative pottery of Japan. Bizen Ware is a popular pottery with ancient traditions and prestige, and is valued highly, as some of the most famous kilns have produced artists and craftsmen who have been designated as living national treasures. Having said that, modern Bizen ware is not so expensive that its unaffordable. After the Kamakura period (around 1185 to 1333 A.D.), Bizen Ware was no longer used solely by nobles and aristocrats, but was also popular as everyday utensils used by samurai and townspeople alike. The beautiful brownish and reddish color surfaces of Bizen Ware are created by the minerals contained in the special clay obtained in the vicinity of Okayama. It's fired by covering it with oily pine ashes and placing straw over it so that it is in direct contact with the flame. By firing it at high temperatures, the minerals contained in the clay become vitrified, increasing the strength and luster of the surface. Because no chemicals are used, the texture is not smooth like porcelain, but rugged with a rustic texture. How Bizen Ware is Made Source :YouTube screenshot 1. Kneading the clay (Video 0:34~) Bizen Ware commonly uses clay that lies 3-5 meters below the surface of a rice field. 2. Molding (Video 0:48~) Remove the air from the clay making it sticky and preventing cracks and crevices from forming. A potters wheel is used here. 3. Drying (Video 1:29~) Allow it to dry thoroughly. 4. Setting in a kiln (Video 1:44~) Pieces are carefully placed into the kiln to achieve the most beautiful firing results. 5. Firing the kiln (Video 2:28~) Each piece is fired for more than 10 days. Bizen Ware Patterns as Shown in the Video Source :YouTube screenshot You can see the finished pieces in the video. ・Goma (Video 3:03~) Ashes from the firewood fall on the pieces during the firing process. The ashes react with the soil and become vitrified, creating a variety of patterns. ・Sangiri (Video 3:12~) Charcoal is thrown into the kiln at the end of the firing process to create a pattern of contrasting color changes from white, blue, and yellow in parts. ・Hidasuki (Video 3:20~) This pattern is created by the reaction of the alkaline content of the straw and the iron content of the base material. Summary of Okayama's Bizen Ware Photo:Bizen ware The other name for Bizen Ware "Inbe Yaki" (Imbe Yaki) came from the local place named "Inbe." Now there are many Bizen Ware Pottery kilns and studios with galleries around Inbe Station in Okayama Prefecture, and the Bizen Ware Festival (also called the "Bizen Pottery Festival") held every autumn attracts many pottery fans and tourists from all over Japan. Even today, Okayama Prefecture promotes the history and culture of traditional Japanese crafts through Bizen Ware works. There are everyday products that can be used for everyday living, such as mugs and glasses for beer as well. 【Official Website】Bizen Ware | Traditional Crafts | Japan Traditional Crafts Aoyama Square https://kougeihin.jp/en/craft/0418/ -

Video article 4:15

Video article 4:15Hand-dyeing yuzen dyeing of gorgeous kimono, a delicate traditional Japanese technique delicately drawn by craftsmen at a workshop in Kyoto City, Kyoto Prefecture, Japan, in a video.

Traditional Culture- 260 plays

- YouTube

Video introduction of Ikeuchi Yuzen, a hand-dyed yuzen dyeing studio in Kyoto City, Kyoto Prefecture, Japan. This video, titled "Ikeuchi Yuzen - Forms of Yuzen Dyeing, an Art That Gives Color To the Modern World / IKEUCHI YUZEN" (池内友禅~現代を花やかに彩る友禅染のかたち~), was released by "Yuzen Ikeuchi." It introduces the manufacturing process of Yuzen Ikeuchi, a type of Yuzen dyeing. Yuzen dyeing, which is used for Japanese kimono, is a traditional craft that represents the Genroku culture that blossomed in Kyoto and Osaka in the middle of the Edo Period. The name "Yuzen" comes from Miyazaki Yuzen, a fan painter who invented Yuzen dyeing during the Edo Period. A Look at Ikeuchi Yuzen, a Type of Yuzen Dyeing Introduced in the Video Source :YouTube screenshot Yuzen Ikeuchi is a Yuzen dyeing workshop in Arashiyama, Kyoto. In the old-fashioned workshop, various works such as homongi (One of the types of Japanese women's kimono), furisode, and kimono accessories are made. In his work, Yuzen dyeing artist Masahiro Ikeuchi, introduced from 0:34 in the video, tries to express the magnificence of humanity while being inspired by the splendor of nature in Japan. The Yuzen Dyeing Techniques Introduced in the Video Photo:Kyoto Hand-Drawn Yuzen A major feature of yuzen dyeing, a traditional Japanese craft, is the delicacy of the patterns. Yuzen dyeing is all hand-dyed and uses a starchy resist dye. In the past, yuzen involved washing the fabric in the river after it was dyed. There are various types of Yuzen dyeing, such as Kyo Yuzen, Kaga Yuzen, and Tokyo Yuzen. Each dyeing technique is different, and you can enjoy the different patterns of each style. A Look at the Yuzen Dyeing Introduced in the Video Source :YouTube screenshot So how is Yuzen dyeing done? Let's take a look at the main steps in the dyeing process. 1. Zuanzukuri (図案作り): Drawing a design 2. Aobana Utsushi (青花写し): Copying the design onto the fabric 3. Itomenori-oki (糸目糊置き): The process of putting anti-dye paste around the patterns to be dyed. 4. Ji-ire (地入れ): Stretching the fabric to prevent unevenness in color that may occur later. 5. Yuzen-sashi (友禅挿し): After the fabric is stretched, the patterns are filled in with a brush. 6. Noribuse / Roubuse (糊伏せ / ロウ伏せ): The dyed patterns are covered with rice glue or wax to prevent the background color from seeping into them. 7. Hikizome (引き染め): Hikizome is the process of dyeing the background color of the fabric with a brush. 8. Mushi (蒸し): Mushi is a process of fixing the dye to the fabric using steam power. 9. Mizumoto (水元): Mizumoto is the process of rinsing off excess dyes and glues left on the fabric from the previous processes with water. 10. Yunoshi (湯のし): Yunoshi is a finishing process, in which steam is applied to the shrunken or distorted fabric in order to remove wrinkles and align its length and width. 11. Some-agari (染め上がり): After the mushi, mizumoto, and yunoshi steps are completed and the glue and wax are removed, the lines of the threads appear clearly and the dyed patterns emerge vividly. 12. Shiage / Kinkako / Shishu (仕上げ / 金加工 / 刺繍): The process of decorating the dyed fabric with gold leaf and embroidery to make it gorgeous. 13. Shitate / Karieba (仕立て / 仮絵羽): Karieba is the process of sewing a single, fully processed piece of cloth into the shape of a kimono. The kimono made through these processes are incredibly beautiful. In the video, you can see a woman wearing a Yuzen-dyed kimono walking through the streets of Kyoto. Summary of Yuzen Dyeing, a Traditional Craft of Kyoto Photo:Kyoto hand-dyed Yuzen Yuzen dyeing is done with the precise hand-dyeing techniques shown in the video. The beautiful patterns have fascinated people for many years. On top of the traditional patterns, there are also a number of modern pieces of Yuzen dyeing, so you're sure to find one you like! -

Video article 3:52

Video article 3:52You Won't Be Able to Take Your Eyes off the Amazing Skills of This Female Chef Cooking up a Yakisoba Storm! Yakisoba Is a Popular Food Found at Festival Food Stalls in a Variety of Styles!

Food & Drink- 576 plays

- YouTube

Yakisoba at Japan's Festival Stalls This video, titled "Japanese yakisoba street food japan how to make yakisoba" (物凄い焼きそば女職人 焼きそば屋台 職人芸 無修正 ノーカット Japanese yakisoba street food japan how to make yakisoba[飯テロ公式]), was released by "JAPAN FOOD 〜 The Ultimate Food Porn 〜" (JAPAN FOOD 〜最高の飯テロ〜). The video shows how yakisoba is made at food stalls at festivals in Japan. In the video, the yakisoba chef works quickly to prepare a huge amount of yakisoba, an amazing feat that you'd be hard pressed to imitate. Check out the amazing skills in the video! How Delicious Festival Yakisoba is Made! Photo:A yakisoba stand Yakisoba is a popular food that is relatively easy to make at home. Prepare some Chinese noodles and cabbage, throw it into an oiled pan, add water and fry it up. After stir-frying the noodles, season with yakisoba sauce. We recommend trying it with some mayonnaise or adding pickled ginger on the side, two authentic ways of serving it in Japan. Yakisoba sold at Japanese food stands are generally sold in small plastic containers, as shown at 3:38 in the video. What is the charm of the yakisoba stand that is shown in the video? Photo:yakisoba stand Of course, homemade yakisoba is delicious, but there's just something about the yakisoba at festivals that will have you coming back for more. The food stands found at festivals across Japan use plenty of ingredients, and season them all at once with tasty seasonings. Making a lot of yakisoba at once is a lot of work, especially when doing it for hours on end. As a staple food of festivals, yakisoba can be purchased at a reasonable price, generally costing around 200 to 500 yen, depending on the area. Different Varieties of Yakisoba Photo:Yakisoba sandwich There are many different recipes for yakisoba, so try cooking it at home or if you're in Japan, be sure to visit a specialty store. Yakisoba sanwiches with yakisoba sandwiched between a hotdog bun is popular as a light snack that anyone can enjoy. There are also local recipes from different regions of Japan, such as omusoba and sobameshi. Yakisoba can be seasoned in a number of ways. In addition to yakisoba sauce, there's also yakisoba made with Worcestershire sauce, soy sauce and oyster sauce, salt and pepper, and even miso. Summary of Japan's Delicious Yakisoba Stands Photo:A yakisoba stand The video introduced in this article shows how large amounts of yakisoba is made at festivals in Japan. It's quite impressive, and if you haven't eaten yet, it might just have you in the mood for some tasty noodles! Be sure to try some delicious yakisoba when visiting any of Japan's exciting festivals. -

Video article 3:52

Video article 3:52Murakami Kibori Tsuishu - A Traditional Craft of Niigata Prefecture That Dates All the Way Back to the Heian Period! Discover the Unique Process Used To Make Them in This Video!

Traditional Culture Traditional Crafts- 98 plays

- YouTube

Murakami Kibori Lacquerware - A Traditional Craft of Niigata Prefecture This video, titled "手技TEWAZA「村上木彫堆朱」Murakami Kibori Lacquerware/伝統工芸 青山スクエア Japan traditional crafts Aoyama Square," was released by "Traditional Crafts Aoyama Square." Murakami Kibori Lacquerware (Murakami Kibori Tsuishu), introduced in the video, is a general term for six types of carving, including tsuishu, tsuikoku, and shumarinuri, and it is a traditional craft of the Murakami region of Niigata Prefecture, which has been widely known as a natural lacquer production area since the Heian period (794-1185). Murakami Kibori Lacquerware was introduced by a lacquer maker in Kyoto at the beginning of the 15th century as a technique for painting lacquer on wood carvings. This was done in imitation of Chinese tsuishu (lacquerware), and the technique was introduced to the Murakami region after a temple was built there. The technique was first learned by the carpenters who built the temple, after which it was was passed on to samurai duringEdo period (1603-1868), then to the townspeople, and finally to present day Japan. In this article, we'll go over Murakami Kibori Lacquerware, a traditional lacquer technique of Niigata prefecture. The Process of Making Murakami Kibori Lacquerware Source :YouTube screenshot Along with the video, we'll be introducing some of the steps in the 18 to 20 step process that craftsmen use to make Murakami Kibori Lacquerware by hand. 1. Sketching (0:40~) This serves as a guide for engraving and is drawn directly on the wooden plate. Drawing with a brush that can express stronger and weaker lines is fundamental to the process. 2. Carving (0:47~) Wood carving is performed by using a chisel called an "Urajiro" on the sketch drawn in step 1. There are two types of carvings, the two-dimensional Shishiai-bori and three-dimensional Hikisage-bori. In the video, the craftsman explains that the most important thing is to carve the wood as though it were a living thing, making the most of the different grains of each tree. 3. Sanding (1:18~) This is the process of sanding the roughness of the blade marks with sandpaper (in the old days, horsetail was used) to give roundness and softness to the carving. This makes the work even more three-dimensional. 4. Hardening This involves adding a small amount of red husks to raw lacquer and using a brush to soak the entire wood with lacquer. This is also an important step because it is done to solidify the foundation of making a durable Tsuishu. Source :YouTube screenshot 5. Smoothing (1:29) In the important undercoating process to make durable lacquerware, raw lacquer and polishing powder are mixed and applied 2-3 times to the plain areas without engravings. 6. Polishing The process of water-polishing the coated surface using an imperial whetstone. This is done with applying rust lacquer and is repeated 2-3 times and the lacquerware is allowed to dry for at least a few days after the rust lacquering process. 7. Middle Coating (1:40~) The process of dabbing on lacquer on with a pad or fingertip and then finishing painting with a brush so that the engraved pattern is not filled with lacquer. Generally, oil-free refined lacquer is used for this. 8. Polishing the Middle Coating It is a process of carefully water-sanding the surface with a fine-grained natural stone whetstone called Murakami whetstone or a water file. 9. Top Coating (2:06~) Brightly colored vermilion lacquer is dabbed on with a pad or fingertip and finished painting using a brush so as not to fill the carved patterns similar to the intermediate coat. Source :YouTube screenshot 10. Matt Finishing (2:23~) An important process for polishing the top-coated glossy surface with charcoal or polishing powder evenly with water to make it a deep and calm-looking product. 11. Engraving (2:44~) The designs are carved once more. This fine carving is made to supplement the earlier wood carving with a fine-pointed triangular chisel. Expressions such as leaf veins, feathers, and mountain surfaces are re-engraved. 12. Finishing (3:06~) This step involves adding a small amount of red iron oxide to high-quality raw lacquer and rubbing it with a brush over the entire vessel. The matte surface is moist and firm, and this completes the production process of Murakami Kibori Tsuishu. The beautiful, finished product, like a work of art, can be seen from 3:23 in the video. These unique techniques have been designated Intangible Cultural Properties of Niigata Prefecture and Murakami Kibori Lacquerware was designated a National Traditional Craft. Summary of Murakami Kibori Lacquerware, A Traditional Welcome Gift of Niigata Prefecture Source :YouTube screenshot Murakami Kibori Lacquerware, a traditional craft that has been handed down since the Heian period, includes products such as jubako (stacked boxes), sake cups, tea ware, flower ware, confectionery ware, sake ware, etc. that are all great for celebrations, souvenirs, and gifts. Murakami Kibori Lacquerware is a testament to the living history of Japan, through which you can enjoy the techniques that craftsmen have refined and passed down since ancient times. 【Official Website】Murakami Kibori Lacquerware | Traditional Crafts | Traditional Crafts Aoyama Square https://kougeihin.jp/en/craft/0509/ -

Video article 19:33

Video article 19:33Glass beads left at Byodoin Temple in Kyoto were restored by Izumi Dragonfly Ball craftsmen in Izumi City, Osaka Prefecture! The brightly colored dragonfly beads are a “universe in glass!

Traditional Crafts- 317 plays

- YouTube

Promotional Video Introduction of Izumi Dragonfly Ball Craftsman in Izumi, Osaka This video, titled "#118 Izumi Tombodama Craftswoman – Matsuda Yuki - Door to Tomorrow by At Home" (#118 和泉蜻蛉玉職人 松田 有綺 | 明日への扉 by アットホーム) by "Door to Tomorrow by At Home," is from a television program broadcast on tv in July, 2019. This 20-minute long video was originally broadcast in four parts and we highly recommend watching it if you're interested in any of the following: ・Learning more about the restoration of the national treasures of Byodoin Temple in Kyoto. ・Gaining insight into how traditional Japanese glass beads ("Tombodama") are made. ・Learning more about the Izumi Tombodama craftsman who is working hard to preserve Japanese culture. Yuki Matsuda (松田有綺), the craftswoman featured in the video, continues to work hard acquire the skills necessary to pass on Japanese culture to future generations. You can see Yuki Matsuda from 1:31 in the video. In this article, we'll go over how Japan's Tombodama are made and how the Tombodama found in Kyoto's Byodoin Temple have been restored, alongside the video. Restoring the National Treasures of Kyoto's Byodoin Temple Source :YouTube screenshot The glass beads found in the base of the wooden Amitabha statue found in Byodoin Temple's Hoodo hall (鳳凰堂) were part of a decoration called a "Yoraku" (瓔珞) that used to hang in the area surrounding the Buddha statue. You can see the beautiful glass beads from 0:58 in the video. They are thought to have been made in the same workshop as the items stored in Shosoin (正倉院), athe treasure house of Todaiji Temple in Nara. The beads of the Yoraku decoration mentioned above were restored by Osaka craftswomen Yuriko Matsuda (松田有利子). You can take a look at the restored glass beads at 1:32 in the video. The glass stored in the Sangetsu Kobo Workshop (山月工房) were found to be similar in composition to the glass glass beads from Kyoto, which have been designated national treasures, and was therefore used in the restoration project. How are Izumi Tanbodama Glass Beads Made? Source :YouTube screenshot First, the glass is heated and stretched into long threads which are then broken into smaller pieces to create the glass used to decorate the beads. The glass bead making process is as follows: ・A metal rod coated with a stripping agent (剥離剤) is heated ・Several glass rods are then heated together ・The softened glass rods are then wrapped around the metal rod ・Small pieces of broken glass are then attached to create a particular design ・A tool is used to manipulate the shape of the glass and create a design on the outside of the bead ・The finished bead is cooled by covering it in ash You can watch the whole process from 6:52 in the video as Izumi Tanbodama craftswoman Yuki Matsuda demonstrates how the glass beads are made from start to finish. Izumi Tanbodama Items Available For Purchase Source :YouTube screenshot Jewelry such as necklaces and bracelets as well as traditional Japanese clothing items and accessories like Obidome (帯留め, obi sash clips), Kanzashi (簪) and Netsuke straps (根付ストラップ) are just some of the glass bead items available for purchase. There are also items made from glass similar to that of the glass beads found in Byodoin Temple in Kyoto, with prices varying depending on the method used to make the beads. For example, an incense holder made from glass similar to that of the National Treasures in Kyoto costs around 5000 yen. Summary of Izumi Tanbodama Glass Beads Photo:Byodoin Temple's Phoenix Hall, Kyoto From 16:12 in the video, you can watch the craftswomen as they visit Byodoin Temple in Kyoto to take a look at the National Treasures they themselves restored. Yuki Matsuda speaks of how she hopes to use her craft to create not only beautiful objects, but memories to go with those objects. If you are interested in Japanese culture or wish to know more about how Izumi Tombodama are made, we highly recommend you watch the video! -

Video article 9:47

Video article 9:47Wadaiko, a traditional Japanese craft that plays dynamic music at festivals and other events, takes several years to complete!This is a video of a taiko drum craftsman in Hakusan City, Ishikawa Prefecture, who preserves the technique!

Traditional Crafts- 242 plays

- YouTube

Video Introduction of Japanese Drum Artisans in Hakusan City, Ishikawa Prefecture "# 005 Wadaiko Tetsuro Sugiura: Door to Tomorrow by At Home" is an interview with the Wadaiko craftsman introduced in the Discovery Channel program "Tomorrow's Door." Tetsuro Sugiura, a wadaiko craftsman of "Asano Taiko" in Japan's Hokiriku region, Hakusan City, Ishikawa Prefecture, trained long and hard before becoming a full-fledged wadaiko craftsman. This time, let's take a closer look at Japanese traditional crafts, and the technique used for making Japanese drums, which takes several years to learn. About the Traditional Culture of Japanese Wadaiko Introduced in the Video Photo:Wadaiko Wadaiko is one of the Japan's historical musical instruments that is played at festivals that are held all over Japan, such as Kyoto and Fukuoka. It is also used at ceremonies at shrines and temples, as well as for Kabuki and Noh. Its origin dates way back, and the oldest Japanese taiko drum was excavated from the remains of the Jomon period (14000 BC- 400 BC). A Japanese drum (Wadaiko) is a percussion instrument that is made of wood and has a body covered with leather. There are various types of Japanese drums that are currently used, such as a long drum, tub drum, and an attached drum. How Wadaiko Are Made Source of photo :YouTube screenshot The production process of the traditional Japanese drum, Wadaiko, is introduced in detail from 2:09 in the video. The two main tasks to make the taiko, are the making of the body and the making of leather. A Japanese drum craftsman cuts down a zelkova tree, which is then used as a raw wood without any treatment. They then cut the body of the zelkova and roughly forms it into its final shape, which is then naturally dried in a cool and dark place for 3 to 5 years. The carving on the inside of the drum is beautifully hand-crafted to have a tortoiseshell or diamond-like pattern. You can see the inner carving process from 3:01 in the video. Source of photo :YouTube screenshot Next, as you can see from 3:18 in the video, a refined technique is essential for lacquer painting. In the process of making leather, from 3:25 in the video, the skill of the Japanese drum craftsman integral to creating the beautifully processed cowhide, which will cover the drum. After putting the leather over the drum the sound is checked, and if sufficient, tacks are attached to complete the work. You can see the finished product from 4:43 in the video. Each taiko drum takes several years to complete and many craftsmen are involved in the crafting process. From 4:56 in the second part of the video, you can see the craftsmanship of the Japanese drum artist Tetsuro Sugiura, who is a leather craftsman. An interview with Mr. Tetsuro Sugiura is introduced in detail where he talks about the process of leather making, which is the cornerstone of each drum's sound. Summary of Japan's Traditional Wadaiko Craftsmen Source of photo :YouTube screenshot The video shows the long and delicate process of making large Japanese taiko drums. No special qualifications are required for the production of wadaiko, but long and rigorous training is required to craft wadaiko that produce beautiful, dynamic sounds of art. This craft relies much on feel, and thus requires diligent and highly skilled Japanese drum craftsmen. 【Official Website】Asano Taiko https://www.asano.jp/en/ -

Video article 13:16

Video article 13:16Bingata - Traditional Resist Dyeing of Okinawa, Japan, Used to Make Kimono With Breathtaking Designs and Colorful Patterns

Traditional Crafts- 243 plays

- YouTube

Bingata - A Traditional Japanese Craft This video, titled "BINGATA – Az okinawai textilfestés," was created by "Teodora Vegh." It introduces Rei Ishida (石田麗), who currently makes Bingata in a workshop in Oita Prefecture (大分県). Bingata is a traditional dyeing technique representative of Okinawa, and is sometimes referred to as "Ryukyu Somemono" (琉球染物). This dyeing technique is used to create beautiful clothing items and accessories which are available for purchase. Check out the video to learn more about the history of this traditional craft and how Bingata products are made! The History of Bingata, A Traditional Japanese Craft Source :YouTube screenshot The Bingata dyeing technique has been used in Okinawa since the 13th century. It's said that this technique was developed to create kimono for the royal family at the time. The kanji characters for "Bingata," which until then was simply written in hiragana, were chosen during the Showa period (1926 AD - 1989 AD). Since the Second World War, Bingata workshops have opened up all over Japan and items are now produced as works of art. How Bingata is Made Source :YouTube screenshot The craftsmen must first design and create a stencil that will be used to apply a motif to the fabric. The stencil is cut out carefully by hand. This process can be seen at 0:40 in the video. Once the stencil is made, a paste is applied on top of the stencil (1:38 in the video) followed by paint to apply color to the material. The brushes used to dye the fabric are often made from human hair. Other dyeing methods such as Tsutsugaki (筒描き) and Aizome (藍染) are often used, as well as the traditional Bingata dyeing technique. After applying color, the fabric is then steamed and soaked in water to remove the paste. The Bingata dyeing process shown in the video is as follows: 1. Design 2. Stencil carving (0:39~) 3. Paste application (1:44~) 4. "Gobiki" (2:36~) 5. Color application (3:05~) 6. "Sumitori" (4:03~) 7. Steaming 8. Soaking 9. Nori paste application 10. Dyeing 11. Steaming 12. Soaking 13. Sewing 14. Finish Purchasing Bingata Dyed Goods Source :YouTube screenshot Bingata fabric is used to create many items such as furoshiki (風呂敷), tapestries, accessories, kimono, yukata, furisode (long-sleeved kimono) and hanhaba obi (half-width obi/kimono sash). The bright, bold coloring of Bingata dyed goods is typical of Okinawa. Bingata items can be purchased in workshops and gift shops around Okinawa and Kyushu. In recent years, the number of Bingata items being sold online has been increasing making it even easier to find and purchase the patterns that suit you best. Summary of Bingata, A Traditional Craft of Okinawa Source :YouTube screenshot Making beautiful Bingata dyed goods like those introduced in the video involves a series of complicated processes. Clothing and accessories made from Bingata dyed fabric make great Japanese souvenirs! Have fun searching for your favorite Bingata goods! -

Video article 1:55

Video article 1:55An Impressive Video of Chefs Preparing Eel at the Famous Restaurant Kawatoyo in Narita, Chiba. Take a Look at the Flashy Skills Catching the Eyes of Passersby!

Food & Drink Traditional Culture- 554 plays

- YouTube

Video introduction of how to cook eel at "Kawayo" eel restaurant in Narita City, Chiba Prefecture. The video, taken at Kawatoyo, a Meiji style restaurant situated on the way to the Naritasan (Narita Mountain) Shinshoji Temple in Narita, Chiba, shows how the chefs prepare Japanese eel (Unagi) before cooking them. There is a common saying among eel restaurant chefs that gives some insight into how difficult mastering the techniques behind their job is, it goes: “Three years of skewering, eight years of cutting, and a lifetime of grilling.” In spite of the difficulty of this job, the chefs in the video make it look easy, and even enjoyable. In just two minutes, one can easily understand how skilled the chefs at Kawatoyo are. Be sure to follow along with the video as you read the article! Grilled Eel, Narita’s Specialty Photo:Eels When most people think of Narita they think of eel. And it's no surprise either. With its 60 eel restaurants Naritasan, Omotesando has become a popular attraction for both tourists and food lovers alike, and it is conveniently located just a 15 minute walk from the JR Narita Station. Kawatoyo is a well-established shop in Narita, serving grilled eel since 1910. Crowded even on weekdays, part of its popularity is due to the show offered by its chefs working in front of diners. This can be seen in the video as well The skillful maneuvering of tools and knives done on the restaurant's large wooden cutting board, catches the eyes of many tourists, who are impressed by the fascinating sight. Source :YouTube screenshot These are the steps to prepare the eel. Be sure to follow along with the video: 1. Nailing the eel to the board 2. Cutting it open with a knife 3. Gutting it 4. Boning it 5. Slicing it to proper size Because of how difficult it is to perform this procedure both quickly and accurately, apprentices are usually relegated to applying the skewers. Unlike other fish, eels must be killed just before preparing them as their flesh tends to spoil very quickly: so quickly that the speed at which the preparation work is done ends up influencing the taste of the final product. In addition to that, raw eel blood is toxic, and while cooked preparations are safe to eat, handling and preparing the raw product requires great care on the chefs’ part. Some Final Words on Narita Eel Photo:Eel bowl On a normal weekday, the chefs at Kawatoyo prepare a staggering 400 eels for their customers, and this number doubles to a whopping 800 on weekends and holidays. The taste of the grilled eels you can have in this wooden, old fashioned traditional Japanese shop is simply amazing. There are various eel recipes and serving styles in Japanese cuisine: be it rolls, unagi sushi, eel served in traditional wooden boxes or on top of rice bowls. Did you know that grilled eel cooking methods can vary from region to region in Japan? In the East, Kanto-style eels are sliced open from the back, then steamed and only later grilled, making for a richer, more plump texture, while in the West it is more common to have them Kansai-style, following a method that focuses on fragrance and crispness by grilling the eels on their belly directly over a flame. The best you can do is walk your way through Japan and find the style or unagi sauce you like the most. And don’t forget that eels this delicious can only be prepared by skilled, seasoned professionals: do not try this at home! ◆Kawatoyo Honten◆ 【Address】Nakamachi386, Narita, Chiba, Japan, 286-0027 【Access】 By Train 11 minutes walking from JR Narita station 11 minutes walking from Keisei Narita station By Car: 8.3 km from Narita International Airport (about 20 minutes) 3 km from Aeon Mall Narita (about 10 minutes) 2.5 km from Mega Don Quixote (about 8 minutes) 【Open】10 am to 5 pm (last order) 【Closures】None (subject to change) 【Parking】None 【TEL】0476-22-2711 【Official Website】kawatoyohonten http://www.unagi-kawatoyo.com/foreign/index.html -

Video article 4:19

Video article 4:19Koi Are Often Called "Swimming Jewels" and "Swimming Art" in Japan... A Look at the Secrets of These Beautiful Aquarium Fish, Including the Different Varieties and Their Characteristics!

Living Things Life & Business- 1.21K plays

- YouTube