-

Article

-

Traditional Crafts

-

Region

-

Season

-

Tag

Articles

-

Video article 6:41

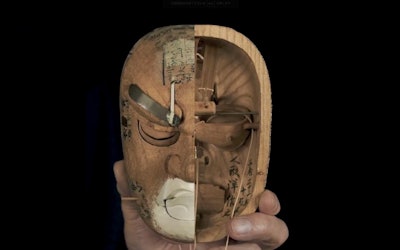

Video article 6:41Exploring the World of Ningyo Joruri - Traditional Japanese Puppet Theater. Discover the Amazing Process of Creating These Priceless Works of Art Made by Skilled Puppeteers!

Traditional Crafts Traditional Culture- 370 plays

- YouTube

Traditional Japanese Performing Arts - Ningyo Joruri This video, titled "Tokushima's Wooden Ningyo Joruri Puppets|Footprints of the Puppets "AWA DEKO" (人形浄瑠璃を支える徳島の木偶 Footprints of the Puppets “AWA DEKO”), was uploaded by Joruri Kaido (浄瑠璃街道). It introduces Ningyo Joruri, a traditional Japanese culture. Ningyo Joruri is a type of puppet theater in which a story is performed by three puppeteers, a tayu (joruri narrator), and a shamisen player. In this article, we'll introduce the puppets behind Ningyo Joruri, a traditional Japanese performing art. The History of Ningyo Joruri, a Traditional Japanese Performing Art Source :YouTube screenshot Awa Ningyo Joruri is a traditional Japanese art form that has been handed down in Tokushima Prefecture for centuries. Ningyo Joruri, which originated in Osaka in the Edo Period (1603-1868) as a form of mass entertainment, is a composite art form in which the tayu, shamisen, and the puppets work together to create a wonderful story. In addition to being enjoyed as a form of mass entertainment, Ningyo Joruri is often performed with the same high artistic quality as bunraku, and performed as a Shinto ritual. The Artisans Behind Ningyo Joruri Puppets Source :YouTube screenshot The puppets used in Ningyo Joruri are called "deko," and most of the heads of deko are hand made by puppeteers in Awa. The construction of the wooden figurines is so elaborate that referring to them any differently would be to disrespect the craftsmanship of the artisans. Awa Deko are a larger variety of puppets used in Ningyo Joruri, so paulownia wood is used as a material to make them lighter. The puppets are designed to manipulate facial expressions and gestures through mechanisms inside their heads, and the craftsman's elaborate techniques are indispensable in creating each masterpiece. You can see how Yoichiro Amari, an Awa Ningyo Joruri Craftsman, creates the puppets at 1:04 in the video. The face is carefully carved out of paulownia wood with a carving knife, cut in two in front of the ears as seen at 2:02, and then mechanisms to control the eyes, mouth, and eyebrows are placed inside the hollowed-out head. Learn More About Ningyo Joruri, a Traditional Japanese Performing Art Source :YouTube screenshot In Tokushima Prefecture, there's "Matsushige-cho Rekishi Minzoku Shiryokan, Ningyo Joruri Shibai Shiryokan," a museum where visitors can learn about the history and culture of Japan’s Ningyo Joruri. At the museum, visitors can learn about the types of puppets, the materials used to make them, how they're made, the techniques used by the artisans, and the steps to completing one. The Tokushima Prefectural Awa Jurobe Yashiki Puppet Theater and Museum (徳島県立阿波十郎兵衛屋敷), where you can see Ningyo Joruri performances up close, is also a great place to visit. If you're looking to experience traditional Japanese culture, we highly recommend stopping by and checking out a performance. Summary of Ningyo Joruri, a Traditional Japanese Performing Art Source :YouTube screenshot The artisans who make the elaborate wooden puppets are essential to Ningyo Joruri, a traditional art form loved by many. We hope you enjoyed learning about the amazing culture of Ningyo Joruri, a traditional Japanese performing art that has been loved through the ages. -

Video article 9:35

Video article 9:35A female dyeing artist from Kyoto, Japan, talks about the fascination of the traditional craft of “Dyeing and Weaving”. How has this thousands-year-old technique been handed down?

Traditional Crafts- 361 plays

- YouTube

Video introduction of the craftsmanship of a female dyeing artist in Kyoto, Japan Source :YouTube screenshot ANA Global Channel aired the video "Artisan of traditional dyeing/Interview - IS JAPAN COOL? CRAFTSMANSHIP" (Artisan of traditional dyeing/Interview - IS JAPAN COOL? CRAFTSMANSHIP(染織家)) featuring female artisan Sarasa Yoshioka. Dyeing and weaving originated in China, India, Rome and Greece, and was introduced to Japan in the 3rd century AD. In the video (2:35), Yoshioka says that the technique is mentioned in the old text "Manyoshu" and the "Engishiki" (a Japanese book about laws and customs) which were both completed during the Heian period (794-1185). The Engishiki documented the ancient dyeing recipes. Having been designated as Intangible Cultural Property, dyeing and weaving technique and textiles such as Kimono and Obi are the important traditional crafts. In this video, female artisan Sarasa Yoshioka, talks about the history of dyeing, a traditional Japanese craft, and her passion for it. It also captures her superior artisanal skills. Magical Patterns Hand-Dyed by Artisans Source :YouTube screenshot There are two main types of dyeing and weaving: Sakizome- in which yarns are dyed first and then woven, and Atozome- in which the cloth is dyed after it is woven. The former is represented by these Kimono makers in the form of Yu-kitsumugi, Nishijin, and Nishikiori. Examples of the latter include Kyo-yu-zen and Kagayu-zen which are known for the splendid picturesque patterns. Sakizome requires a higher skill level than Atozome, and thus Sakizome textiles cost more. The Methods and Materials of Traditional Japanese Dyeing and Weaving Colors are most commonly extracted from plant sources such as roots, tree bark, and nuts. Yoshioka says the plants that are hard to grow are typically supplied by contracted experts (2:08). Indigo dye is one of the oldest and most common dyes to be used for textile dying. Since Indigo has antibacterial and insect repellent effects, it is thought that people wore indigo dyed clothing to keep insects and infections away. The Role of Dyers and Their Delicate Craftsmanship Source :YouTube screenshot The Heian period (794-1185) was the peak of the Japanese Imperial court and aristocratic culture. The garments wore by the upper classes were made by dyeing and weaving artisans. For this reason, dye artisans at that time held a high position in Japan's hierarchical society. The garments wore by the present day Emperor and Empress in the court functions are still made using this traditional technique. These formal court dresses, such as Sokutai and Junihitoe, can only be handmade since the delicate weaving cannot be done by machines. Automated weaving machines were imported to Japan during the Meiji period (1868-1912) and silk textiles were designated as a main industry. Being inferior to the Great Powers in the heavy industries, Japan relied on the techniques of the dyeing and weaving artisans to acquire foreign currency, with the aim of becoming a member of the Great Powers. The Future of Dyeing and Weaving The dyeing and weaving industry, which is both time and labor intensive, has been on the decline for quite some time. Today, however, the increasing number of universities or fashion design schools integrate it in the school curriculum in order to prevent the traditional craft from dying out. The number of young people apprenticed to a dyeing and weaving artisan is also increasing little by little. Kimono, obi, tenugui and other textile products are popular as souvenirs of Japan's overseas markets, and the more opportunities there are for dyed fabric weavers to play an active role, the more likely they are to pass on this traditional Japanese craft to future generations. Traditional Dyeing and Weaving: An Academic Point of View Photo:Dyed goods You may imagine that dyeing and weaving is mainly based on tough outdoor work, but it is also an embodiment of highly developed chemistry. As seen in the video, the majority of plant dyes requires the use of mordant such as vinegar or natural alum to enhance and fix the color in the textile fibers. In other words, dyers obtain the brilliant colors through chemical reactions between the materials. Dye artisans imagine the final product before they even begin. "The color we want to achieve is decided from the beginning, and we use our experience and sense to adjust the color closer to the desired color" says Yoshioka (7:05). In order to achieve the client's desired color, the weavers use all of their wisdom as artisans. Yoshioka says that obtaining the color desired by clients is "a mission given to dye artisans" (7:47). It is not only fabrics, yarns of silk, linen and cotton she dyes, but also washi papers. Every year, she spends the winter months dyeing papers to dedicate to the Buddhist ceremony held at To-daiji Temple in Nara prefecture (5:58). Summary of Japanese Traditional Dyeing and Weaving The video features a dyeing and weaving artisan, Sarasa Yoshioka who works in the Kyoto-based atelier "Somenotsukasa Yoshioka." Sticking to the traditions, the atelier uses only plants dyes and the traditional dyeing method. Dyestuffs are soaked and simmered in the pure spring water of Fushimi (a district in Kyoto), pumped up from 100 meters underground. In this method, a variety of colors and shades can be obtained with the same dye, and the delicacy of dyed fabric is beautiful. In this article, we introduced the history of dyeing, its production methods, origins, and the raw materials used, alongside the interview with craftswoman, Sarasa Yoshioka. In the video, you can see and hear more of what she has to say and also take a look at her technique. Be sure to check it out! Traditional Japanese textiles are available online at retailers such as amazon or rakuten. Using the traditional crafts will lead you to appreciate the value of the traditional craft, as well as the skills of its artisans. 【Official Website】Somenotsukasa Yoshioka https://www.textiles-yoshioka.com/eng/ -

Video article 4:55

Video article 4:55Traditional Japanese Crafts: Akita Woodworking. The History and Culture of Japanese Craftsmen Culminate to Create Beautiful Works of Art in Akita Prefecture

Traditional Crafts- 425 plays

- YouTube

Akita's Traditional Cedar Buckets and Barrels This time, we'll introduce how Akita's traditional Japanese crafts, cedar buckets and barrels, are made. The origin of making craft arts using Akita cedar dates back to before the Edo period (1603A.D.-1868), and after hundreds of years of craftsmanship, a skilled traditional culture had been established. Source :YouTube screenshot Industry in Akita's winter months is harsh, as it is covered in deep snow. Because of this, the people developed woodworking skills, and they mastered the process of making everyday households goods. Because of the high quality and the beautiful appearance of these goods, they have become popular as souvenirs as well. There are many different types as well, not only cedar barrels, but also candy dishes, flower vases, sake barrels, beer mugs, sushi buckets, bathtub buckets, umbrella stands, wooden containers for cooked rice, and more. Many are sold online as well. You can have a look at completed versions of these goods at 4:00 in the video. You can see how the traditional craft is made in the video. The amazing footage is not something you get to see everyday. What Is Akita Cedar? Source :YouTube screenshot The production process of Akita cedar crafts by proficient artisans is shot at a workshop in Odate, Akita. At 1:03 in the video, the artisan describes how Akita cedar is know for its "good color softness, and pleasant fragrance. It can be said that Akita cedar crafts are a suitable material to make a container for preserving foods and daily products. The rich forest in Akita, covered in deep snow, has made the woodworking culture of Akita flourish. Traditional Japanese Crafts- Akita Woodworking Source :YouTube screenshot 1. Cutting panels (0:44). Artisans cut the log to the correct size, and chop the dried materials with various tools. This process is important to make the side of the finished products. Source :YouTube screenshot 2. Formatting panels The tool to shave the planks is called a "sen" (銑). This technique is derived from traditional Japanese sword crafting. Source :YouTube screenshot 3. Fine planing the panels (1:41) The craftsman describes how the "bonded surfaces with no gaps and precise angles are what give the container its integrity." Of the steps in the production process, this is the most important. This delicate step relies on expert handling, experience, and muscle memory. This is where you see the truly amazing skills of Japanese artisans shine. Source :YouTube screenshot 4. Assembling the panels (2:05) Since Akita's traditional wood-works are often used as everyday tools that hold necessities, such as water and other liquids, bamboo nails are used. If you iron nails are used to join the boards, they would rust and eventually break. After the boards are joined, metal hoops are fitted on both the inside and outside surfaces to keep it stable. After the panels are tightened, the metal hoops are removed. Source :YouTube screenshot 5. Fitting the hoops (3:11) A groove is carved out to fit the bottom hoop. Several hoops are fitted on the barrel and firmly tightened. Source :YouTube screenshot 6. Bottom plate adjustments (3:30) The last fine adjustments are made on the bottom plate, removing more gaps, and sanding it the surface is smooth. This traditional Japanese craft truly displays the depths of Japanese craftsmanship. Summary of Akita Woodworking What did you think? Did you enjoy watching the precise craftsmanship of these skilled artisans? These artisans do not take their craft lightly, and as you saw in the video, every step in the process is carefully executed to ensure the highest level of quality. When cutting planks from a log, each plank is categorized as either straight grain or cross grain, based on it's appearance. Each type is properly used for both aesthetic purposes and practicality. The "Akita Woodworking Summit" sponsored by the Akita University Cooperative Society, was held at the Akita Castle ruins near the university in 2019. Many people were able to experience the beauty of Akita woodworking and the skills of traditional artisans. Consider picking up your own traditional Akita woodworking goods and experience the profound culture of Japanese artisans. 【Official Website】JAPAN TRADITIONAL CRAFTS AOYAMA SQUARE https://kougeihin.jp/en/ -

Video article 1:59

Video article 1:59Kokeshi Dolls, With Their Cute Appearance and Expressions, Are Very Popular as Souvenirs and Collectibles Overseas! A Look at Kokeshi Craftsmen and Their Dedication to the Traditional Japanese Craft of Miyagi Prefecture

Traditional Crafts- 403 plays

- Vimeo

An Introduction to Miyagi’s Traditional "Kokeshi" Dolls This video is called ‘Tohoku STANDARD 07 Kokeshi dolls of Sendai City, Miyagi Prefecture (東北STANDARD 07 宮城県 仙台こけし)’ made by Tohoku Standard (東北STANDARD), and it shows you Miyagi Prefecture's Traditional Kokeshi doll. Miyagi's traditional Kokeshi doll has a long history. Its origins trace back to the mid-Edo Period (1603~1868). It was originally a souvenir from onsen hot spring towns in Japan's Tohoku Region. There are five traditional Kokeshi dolls in Miyagi Prefecture: Naruko Kokeshi dolls, Sakunami Kokeshi dolls, Tohgatta Kokeshi dolls, Yajiro Kokeshi dolls, and Hijiori Kokeshi dolls. Their colors and shapes vary by craftsman. Source :YouTube screenshot The video introduces you to Kokeshi doll craftsman, Akira Suzuki from the Ganguan Kokeshi Doll Studio at the Akiu Crafts Centre at the Akiu hot springs in Sendai City, Miyagi Prefecture. He has been working on the restoration of Enakichi Kokeshi dolls by Meiji Period craftsman Enakichi Takahashi. In the interview, Akira Suzuki explains the characteristics of Kokeshi dolls and the tradition that he has been passed on. Watch the video to enjoy the traditional Japanese culture that has been pass down for generations. Sendai's Kokeshi Dolls Photo:Kokeshi doll Kokeshi dolls are popular wooden toys with a simple shape, generally consisting of a spherical head and a cylindrical body, which are used and sold for girls to play with. The body is made in a shape that can be easily held by children. One of the origins of the word, Kokeshi doll is said to be "Kohukeshi," a nickname for them in the Naruko region. Kokeshi dolls have various regional names such as Kiboko, Deku, Kogesu and Hohko. In 1940, at the first local meeting of the Tokyo Kokeshi Society, researchers and artisans debated on the name for the doll and finally decided on "Kokeshi." Source :YouTube screenshot The Kokeshi doll made by Akira Suzuki in the video is a Sakunami Kokeshi doll and it belongs to the category of Sendai Kokeshi dolls. As seen from 0:33 in the video, the characteristics of Sendai Kokeshi dolls are their thinner lower bodies that can easily be held and the simple use of black and red colors. In addition to traditional Kokeshi dolls, Akira Suzuki also creates pretty Kokeshi dolls such as Hyakuso Kokeshi doll shown from 0:57 in the video. Some Kokeshi dolls are made using the traditional techniques and skills passed down through many generations and have maintained their original shapes. Others have a more modern look to suit current tastes, with variations depending on people’s interests at the time of creation. How Kokeshi Dolls Are Made Kokeshi dolls use mainly Cornel and Japanese Maple as materials. It requires the skills of a master craftsman. Production Step 1 - Tamakiri (Crosscutting) and Kidori (conversion) Cutting the dry timber to the suitable length is called Tamakiri, while adjusting the shape of the timber suitable for use for Kokeshi dolls is called Kidori. You cut the timber with a tool such as a saw, then make it into a cylindrical shape by cutting off the corners. This is the foundation of Kokeshi dolls. Source :YouTube screenshot Production Step 2 - Wood turning (~0:14) Set the head and body on the lathe and use a plane to shave the wood. Production Step 3 - Finalizing the shape Once the wood is ground to a certain shape, it is cut and shaped with a finishing planer called a "Bankaki." Next, you use sandpaper to smooth the surface. Source :YouTube screenshot Production Step 4 - Painting (~0:41) Using the lathe, draw lines on the body and add a face on the head carefully. Production Stage 5 - Finish Make a hole in the head and attach it to the body. Other Information About Kokeshi Dolls Photo:Kokeshi doll painting experience In Naruko Onsen, where Naruko Kokeshi dolls are made, they hold the National Kokeshi Doll Festival. Traditional Kokeshi dolls from nationwide gather at the festival, and a festival parade and Kokeshi doll workshops and sales booths are set up. At Kokeshi no Shimanuki in Sendai City, Miyagi Prefecture, you can buy various local folk art and crafts from Japan's Tohoku region. You can also try a Kokeshi doll painting workshop. They sell various Kokeshi doll goods, such as Kokeshi doll in Can, which has a traditional Kokeshi doll packed in a can, and Akari Kokeshi dolls, whose bodies light up and can even be used in emergencies. These items sold at Kokeshi no Shimanuki can also be bought at their online shops. Other popular Kokeshi doll goods include local Kokeshi doll clips made of paper, masking tapes, Kokeshi doll key rings, and Kokeshi doll cakes. Kokeshi dolls with a Sendai Accent which is quite popular, and its postal stamps and LINE stamps are sold. Sendai dialect Kokeshi, a unique character that speaks in the dialect of Miyagi Prefecture, is also popular, and stamps and LINE stamps are also available. The Sendai dialect variation is quite popular because the actress Satomi Ishihara uses it. Summary of the Sendai Kokeshi Dolls Source :YouTube screenshot In the interview (~1:24), Akira Suzuki says, "You can’t keep the tradition alive just by passing it down. We conserve our tradition through innovation." Kokeshi dolls have been popular as a children’s toy for many years. Nowadays, they are popular overseas as souvenirs and collectibles from Japan. If this video has you interested in Tohoku Kokeshi dolls definitely visit the Nihon Kokeshi Doll Museum in Naruko Town. We highly recommend it! Mr. Akira Suzuki looks rather serious in this video's interview, but at the end of this 2 minute video you can tell he is full of love for Kokeshi dolls. By the time you finish this video, we're sure you'll be a fan of Kokeshi dolls too! 【Official Website】Traditional Folk Art of Miyagi – Traditional Kokeshi doll - Miyagi Prefecture Official Website https://www.pref.miyagi.jp/soshiki/shinsan/01kokesi.html -

Video article 2:35

Video article 2:35Aizu Paper Mache Akabeko - With Its Impressive Bright Red Coloring, This 400-Year-Old Folk Art of Aizu, Fukushima Is a Craft That Clearly Shows the Craftsman's Attention To Detail

Traditional Crafts Celebrities- 597 plays

- Vimeo

Aizu Hariko: A Traditional Handicraft of Aizu, Fukushima This video (TOHOKU STANDARD 03 FUKUSHIMA PREFECTURE AIZU HARIKO) was created by “Tohoku STANDARD” and introduces the craftsmen of “Aizu hariko,” a traditional craft that the Aizu region of Fukushima, the birthplace of Akabeko, is proud of. Aizu paper mache is a traditional Japanese craft, local toy, and folk art. During the Warring States Period (1467 to 1573 AD), Gamo Ujisato, the lord of Aizu in the northeastern region of Japan, Fukushima Prefecture, who served Hideyoshi Toyotomi, invited puppeteers from Kyoto to learn the techniques of puppeteering, which he then used to help promote the industry among the common people. In front of Aizuwakamatsu station, there is a huge Akabeko, a traditional craft, local toy, and folk art that has taken root in the area. It is said that the reason why Akabeko is so popular in Aizu is because of the legend of "Akabeko," a herd of red-haired cows that helped rebuild the main building of Enzoji Temple (円蔵寺, Enzoji), home to one of the three major Ākāśagarbha (Bodhisattva of the void) statues in Japan, built approximately 1,200 years ago, which has been passed down through generations. In this video, two craftsmen of Aizu paper mache talk about the history, tradition, and their commitment to the craft. The beauty of the bright red Aizu paper mache is truly an art! Enjoy the beauty of Aizu paper mache! Aizu Paper Mache: Traditional Crafts, Folk Crafts, and Local Toys Source :YouTube screenshot Hariko (paper mache), is formed by attaching paper or other materials to a frame made of bamboo or wood, and is also known as "haribote" in Japanese. The floats of the famous "Nebuta Festival" are also made using this technique. The art of paper mache began in China in the 2nd century and was introduced to Asia and other countries thereafter. Folk art and local toys made of paper mache can be found all over Japan: "Rokuhara paper mache" in Iwate Prefecture, "Sendai paper mache" in Miyagi Prefecture, "Miharu paper mache" and "Inu paper mache" in Fukushima Prefecture, and "Yamagata paper mache" in Yamagata Prefecture. "Yohana" in Tochigi Prefecture, "Takasaki Maneki Neko" in Gunma Prefecture, "Kawagoe Daruma" in Saitama Prefecture, "Edo Inu paper mache" in Tokyo, " Hamamatsu paper mache" in Shizuoka Prefecture, "Paper Plastic Doll" in Toyama Prefecture, " Kobe Suma Macheko" in Hyogo Prefecture, "Dorakukan Kobo" in Okayama Prefecture, "Miyajima Macheko" in Hiroshima Prefecture, "Takamatsu Miyauchi paper mache" in Kagawa Prefecture, " Paper mache Whale Cars" in Kochi Prefecture, and "Tosa Washi" in Kochi Prefecture, “Plaster paper mache” in Okinawa Prefecture. Aizu Hariko is characterized by its bright red coloring, and is mainly made in prayer for child-rearing, good luck, thriving business, and to bring a good harvest. The two Aizu Hariko artisans in the interview in this video are the writer "Toyorin" of "Nozawa Folk Crafts" and his daughter "Minako Hayakawa." "There used to be about 30 Akabeko paper mache craftsmen, but they all had different shapes and made the same thing for 50 years," says Toyorin (0:33). However, from 1:48 of the video, Minako Hayakawa said, "Although it's necessary to inherit the parts that need to be inherited, but it is also important to innovate and make something that fits people's tastes if you want to survive. While certain things may change, the fundamentals remain the same." The interviews convey the struggle of the artisans to preserve tradition, but also their struggle to breathe new life into it due to practical issues such as the lack of successors and the decline of tradition. How Aizu Hariko Are Made Source :YouTube screenshot In this video, on top of the interview, we see the making of Akabeko at 0:31 in the video. In this article, we'll go over the steps of how to make a common Akabeko paper mache. Be sure to take a look at their delicate craftsmanship as you follow along. Materials: paper, soil, wood, straw, bamboo. 1. A wooden mold is shaped, and a number of sheets of Japanese paper are pasted to it with glue and dried. (Video: 0:31-) 2. When the glue dries, the back and belly are opened with a small knife and the wooden mold is removed. 3. After the wooden mold is removed, Japanese paper is pasted over the mold again and re-coated with a special paint. 4. A top coat of red dye or similar material is used to apply the color. (Video: 0:53-) 5. Patterns are then drawn on the surface with ink. (Video: 1:26-) 6. Finally, the head is attached and it's finished. (Video: 1:45-) The completed red Akabeko can be seen at 1:22. They're truly masterpieces! Aizu Paper Mache Source :YouTube screenshot Nozawa Folk Crafts introduced in this video, deals with various products. The new colorful folk craft, "wish balls," introduced at 0:02 in the video, were made to aid in the recovery from the 2011 triple disaster. There are various types of paper mache toys, "zodiac paper mache," which are paper mache tinctures shaped like the animals of the Chinese zodiac, such as rats and boars, and which bob their heads back and forth to bring good luck. Many different varieties are sold every year. In the year of the dog in 2018, the "Zarukaburi Dog" (A dog wearing a basket on its head) was very popular. There's "Matryoshka" toys reminiscent of babushka dolls, with eggs inside chicks, inside chickens, "Wedding Koboshi," "Okiagari-koboshi," "Aizu Tenjin," "Fukkomaru" and "Fukumasu," made to aid in the recovery of the 2011 triple disaster, as well as Akabeko, Fukubeko, Senryo-beko, Okame, and Hyottoko masks. These are just some of the different types of Aizu paper mache. These products can also be purchased via Amazon or Rakuten online shopping websites. In Yanaizu, the birthplace of Akabeko, you can see Akabeko everywhere in the city. At the "Rest House Hotto in Yanaizu," you can try your hand at painting in a special space inside the building. Why not try your hand at making your own original Akabeko? Summary of Aizu Paper Mache This traditional craft has been handed down in Japan for a long time, and the craftsmen are very particular about their work and their struggle to pass it on to the next generation. This article and video were just a small look into the world of Aizu Hariko Craftsmen. You can see from the video that the long-loved craft is made by the amazing skills of passionate craftsmen. We hope that this traditional Japanese craft will continue to be passed on for many years. 【Official Website】Nozawa Folk Crafts http://www.nozawa-mingei.com/index.html -

Video article 2:45

Video article 2:45The Gorgeous Carp Streamers of Kazo Saitama; One of the Few Carp Streamer Towns in Japan. The History of These Handmade Crafts and How They're Made!

Traditional Crafts Traditional Culture Celebrities- 676 plays

- YouTube

The Traditional Carp Streamers of Kazo, Saitama The video "Kazo Carp Streamers [Saitama Prefectural Government Official Sightseeing Video]"(加須の手がき鯉のぼり【埼玉県公式観光動画】)” was created by “ChokotabiSaitama,” and it introduces viewers to the traditional hand-painted carp streamers of Kazo, Saitama, in Japan's Kanto region. May 5th is Children's Day in Japan. People put up carp streamers to exorcise bad spirits and as a way to respect children's personalities and to celebrate their happiness. Kazo is known as the No. 1 producer of the Japanese traditional carp streamers. It also creates the dynamic hand-painted carp streamer. Carp streamers have become a Kazo specialty that every Kazo citizen is proud of. This video will show you how these hand-painted carp streamers are made! You can also visit the factory and have a factory tour. The History of Kazo's Hand-Painted Carp Streamers Kazo carp streamers were originally created in the early Meiji period (1868-1912) as a side job for craftsmen who usually made lanterns and umbrellas. This traditional high quality handmade carp streamer gradually gained popularity and Kazo became the number 1 carp streamer town. Masaru Hashimoto, a traditional carp streamer craftsman from the long-established carp streamer studio, Hashimoto Yakichi Shop in Kazo City, has been producing carp streamers for a long time. Unfortunately, his store closed down in 2016 after 109 years of business. Kazo Carp Streamers: How They're Made Source :YouTube screenshot 1. Cutting and sewing (0:32) In order to make these hand-painted carp streamers, you start by cutting the fabric into a carp shape and sewing it together. 2. Memawashi (1:07) Draw eyes by using a special compass to draw circles. 3. Sujigaki (1:22) Draw scales one by one using lightly colored ink. 4. Usuzumi (1:30) Add color to the scales. Adding colors is the part that requires the most focus. 5 Kinbiki (1:49) Add the finishing touches with a specialized brush. As you can see in the video, the technique used to finish the painting process is very precise. The masculine expression of the carp and intricate scales are drawn with the precise technique of the craftsman. Gigantic Kazo Carp Streamers As Kazo is known as the No. 1 carp streamer producer in Japan, they also make the world biggest carp streamer. The jumbo carp streamer is 100 meters long! The jumbo carp streamer, which was made by Kazo citizens, appears at the Tone river riverbed every May, at the Kazo City Heiwa Festival (Jumbo Carp Streamer swim). Check out the event to see the jumbo carp stream swimming dynamically in the sky. You can also see the carp streamers made with precise hand-painting techniques. The main venue of the event is at Tonegawa Riverbed Park. 400 parking spaces are available, however, due to the popularity of the event, it will likely be pretty packed. Even though these carp streamers are not the biggest carp streamers in Japan, you can see the carp streamers swimming elegantly under the blue sky at 2:23. These elaborate carp streamers are made through a variety of manufacturing processes, and the video shows the traditional craftsmanship that has been handed down in Japan for centuries. Kazo Carp Streamer Summary Photo:Kazo carp streamers Kazo's hand-painted carp streamers are a very artistic and beautiful creation. Every carp streamer is unique because they are all individually hand made. You can see the traditional Japanese carp streamers every May in Japan. Please come see the carp streamers or try to put one up in your house on Children's Day! -

Video article 2:15

Video article 2:15The Beautiful Shine of Tamamushi Lacquer Ware Is Sure to Captivate You! The Lacquer Ware, Born in Sendai, Miyagi, Was Made Into the Official Product of the Olympics and It's a Popular Choice for Tourists From Abroad. Come Check It Out!

Traditional Crafts- 159 plays

- YouTube

Sendai, Miyagi's Traditional Craft- "Tamamushi Lacquerware" This promotional video titled, "Tamamushi Lacquerware, a Traditional Craft of Miyagi Prefecture"(宮城県指定伝統的工芸品「玉虫塗」), introduces "Tamamushi Lacquerware" a traditional craft of Sendai. It was created by TohokuKogei Showroom. The video lasts for only about two-minutes, so it is perfect for those who want to quickly get to know the history and process of Tamamushi Lacquerware. This article will give you the detailed information on the history of, and facts about Tamamushi Lacquerware alongside the video. Tamamushi Lacquerware is produced in Sendai City in Miyagi Prefecture which is located in Japan’s Tohoku Region; it has a wide range of contemporary products that are sure to please foreign visitors. A Tamamushi Lacquer keepsake box was introduced as an official product of the 2020 Tokyo Olympics. Appreciate the beauty and master craftsmanship behind Tamamushi Lacquerware, the renowned traditional artwork of Japanese culture, through the video. The History of Tamamushi Lacquerware Source :YouTube screenshot Tamamushi Lacquerware is produced in Sendai, Miyagi Prefecture in Japan's Tohoku region. It's very unique, and its stunning glazed finish resulted in it being named "Tamamushi (Jewel beetle)” since they reflect light in the same way a jeweled beetle’s wings do. Tamamushi Phoenix Maki-e (0:11) is another highly regarded type of art. The origin of Tamamushi Lacquerware dates back to a time when they were developed as “exports” at the National Tohoku Craftworks Institute in Sendai in 1932. “TohokuKogei” acquired the patent license in 1939 and has continued creation since. In 1985, Tamamushi lacquer ware was designated as a Miyagi Traditional Craft. Many products with modern designs, such as tumblers and wine glasses, are popular as Japanese souvenirs for visitors to Japan and have become part of Japanese life as a specialty of Sendai, Miyagi Prefecture. The Production Process of Tamamushi Lacquerware Source :YouTube screenshot Just like other lacquerware, The production process of Sendai's Tamamushi Lacquerware begins with making the foundations; they apply lacquer, then polish the lacquerware over and over until the surface is incredibly smooth. Silver dust is spread on a base coating of lacquerware, followed by a coating of colorful red and green lacquer. This process of repeated polishing is what makes it possible for lacquerware to emit it's unique, beautiful gloss. When the lacquer dries, light reflects through the silver underneath. The video shows a craftman spreading silver powder on lacquerware and polishing them. You can also see burgundy-colored lacquer being sprayed on lacquerware at 1:07. The Price and Product Lines of Tamamushi Lacquerware Source :YouTube screenshot Their wide range of products includes trays, vases, teacups, and music boxes, and there are also small hand mirrors, bookmarks, chopsticks, ballpoint pens, and fountain pens. The finished products can be viewed at 1:57. A large metal vase costs at least 80,000 yen, but hand mirrors and chopsticks are quite affordable and make great gifts. They are 1,200 yen and 800 yen respectively. They also launched a collaboration item with the popular Pokemon, Lapras, in 2019. TohokuKogei, introduced in the video, has a showroom in Aoba-ku, Sendai, Miyagi Prefecture. You can purchase regular items and new items such as processed glassware there. Summary- Attractions of Tamamushi Lacquerware- This video shows the production process and techniques of lacquerware, as well as the natural surroundings of Sendai. If you are interested in the world of Japanese traditional lacquerware, which shines like the wings of a jewel beetle, definitely don't miss this video! 【Official Website】The Head Office of “Tamamushi Lacquerware,” TohokuKogei http://www.t-kogei.co.jp/en/ -

Video article 1:51

Video article 1:51Nanbu Tekki Ironware Has Over 400 Years History, Can Be Used for Life, and Is a Very Popular Item Among Foreigners! It Also Acts as an Iron Supplement and Is Good for Your Health. Let’s Take a Look at the Traditional Japanese Product from Morioka, Iwate Prefecture!

Traditional Crafts- 236 plays

- Vimeo

An Introduction to Nanbu Tekki ironware This video, made by Tohoku STANDARD (東北STANDARD), is titled "Tohoku STANDARD 05 Nanbu Tekki ironware" (東北STANDARD 05 岩手県 南部鉄器). In the video, we introduce you to Nanbu Tekki ironware through an interview with Hisao Iwashimizu, an ironworker from Kukan Chuzo Studio. Enjoy the historic, traditional Japanese craft shown in the video! What is Nanbu Tekki ironware? Source :YouTube screenshot Nanbu Tekki ironware is an ironware with more than 400 years of history. Both ironware from Mizusawa, Iwate Prefecture and ironware from Morioka, Iwate Prefecture in Japan's Tohoku region are called Nanbu Tekki ironware. Each has its own history. What we call ‘Nanbu Tekki ironware’ nowadays, is actually the name used in Morioka City, Iwate Prefecture. It is said that ironware started around the time Lord Nanbu of Morioka built Morioka Castle in the Keicho Period (around 1600). There are many Nanbu Tekki ironware products such as pots, cauldrons, wind chimes, candle stick holders, tea kettles, frying pans and kettles. The most famous ones are iron tea kettles used in tea ceremony. It is said that these iron kettles originated when the 28th lord of the Nanbu domain, Shigenao Nanbu , invited Nizaemon Kiyotaka Koizumi of Kyoto to make a chagama with high quality iron. As it was initially used as a tea cauldron, there was no spout nor handle at its conception. After many improvements, the current unique style of tea kettles with a spout and handle was born. It can be seen from 0:47 in the video. Source :YouTube screenshot By using Nanbu Tekki ironware, you can supplement your iron intake which most people tend to be deficient in. Supplementing iron helps in recovery from stiff shoulders, and, as you probably guessed, prevents iron deficiencies. One benefit of boiling tap water in Nanbu Tekki ironware is that most of the chlorine is removed in the process. During World War II, development of arms was given the highest priority and Nanbu Tekki ironware faced a crisis as the production became prohibited in Iwate Prefecture. After the war, it made a comeback, and it was given the status of a "National Traditional Craft" in 1975. How to Make Nanbu Tekki Ironware Source :YouTube screenshot Be sure to follow along from the start of the video! Step 1. Mold cutting Create a wooden mold. Step 2. Pattern pressing Before the casting mold dries, use a tool such as a spatula to draw patterns such as hailstones, tortoiseshells, pine trees, cherry trees, flying dragons, or hills and water. Step 3. Heating the mold Bake the casting mold at 1,400°C with charcoal. Source :YouTube screenshot Step 4. Melting Increase the temperature of the blasting furnace from 1,400 degrees to 1,500 degrees. Pour the melted iron into the casting mold. Source :YouTube screenshot Step 5. Oven bake (~1:17) Take the ironware out of the casting mold and bake it in the oven with charcoal at 800 degrees for 30-40 minutes. Step 6. Coloring/Finishing Using sandpaper, make the surface of the iron kettle smooth. To finish, apply Ohaguro - an iron acetate solution mixed with tea to make it shiny. Summary of Nanbu Tekki Ironware Source :YouTube screenshot At 0:41 in the video, iron worker Hisao Iwashimizu says "I want to recreate the history of Nanbu Tekki ironware as a simple everyday tool." From 0:52 in the video, he also says, "I have launched a product called Yakihada Migaki, where I shave the ironware that has come out of the mold and make it into the form I have in mind." He explains in the interview that he is creating products that have never been made in the history of Nanbu Tekki ironware. If you're interested in Nanbu Tekki ironware after watching the video, be sure to check out Nanbu Tekki ironware online. You can purchase it at online shops such as Rakuten. Popular Nanbu Tekki ironware products are from the long-established Iwachu Nanbu ironware, Kamasada, Suzuki Morihisa Kobo and Oigen. Their products are priced from a few thousand Yen (Tens of dollars). Nowadays, they make new products such as IH compatible ironware, rice cookers using Nanbu Tekki ironware, and colored iron tea kettles (~1:42). You may wonder what happens if it gets rusty. With Nanbu Tekki ironware, you can still use it even if it rusts a little. As long as you look after it, you should be able to use it for life. Be sure to take a look at the video on Nanbu Tekki ironware. It's very popular among people both inside and outside of Japan. 【Official Website】IWACHU Nanbu ironware| Iwachu K.K. Iwachu Morioka, the home of Nanbu Tekki ironware https://iwachu.co.jp/ 【Official Website】Kamasada Nobuho Miya | designshop https://www.designshop-jp.com/japan-onlineshop/ -

Video article 4:17

Video article 4:17Marugame Uchiwa Fans Are Works of Art Whose Craft Has Been Passed Down in Kagawa Prefecture Since the Edo Period. A Look at the History and Production Process of the Amazing Craft, Which Is a Great Souvenir for Visitors to Konpira Shrine

Traditional Crafts Things to Do- 199 plays

- YouTube

Kagawa's Marugame Uchiwa Fans This is a promotional video created by Japan Traditional Crafts Aoyama Square, that introduces the production process of Marugame uchiwa fans, a specialty product of Marugame, Kagawa prefecture. The fascinating craftsmanship of these traditional artisans is a sight to behold. Be sure to follow along with the video as you read this article. The History of Marugame Uchiwa Fans Source :YouTube screenshot Marugame uchiwa fans are a craft that have been produced in Marugame, Kagawa prefecture, also known as Sanuki, since the Edo period. Kagawa prefecture is promoted as the "Udon prefecture" by both the prefecture and the tourism association, with the local specialty being Sanuki Udon. Marugame uchiwa fans were invented by the chief priest of Konpira Shrine in the Edo period (1603 to 1868) as an affordable souvenir for visitors. It was made of inexpensive materials, was lightweight, and came in a variety of designs, making it the perfect regional specialty. It uses Washi which is strong, yet light, and other traditional Japanese materials that are easy to process, such as bamboo. The Marugame uchiwa fans of today refer to the Otokodake-Hirae design (男竹平柄) which was first created in Meiji era. (1868 to 1912) Long-jointed Otokodake is used as the material for the skeleton of the fan, but round Otokodake was used in the original fans. During the Tenmei era(1781 to 1789), when the Marugame clan warriors were making fans as a manual occupation, Onnadake-Marue(女竹丸柄) became mainstream, and in the Meiji era, the "Otokodake-Hirae" became more common as it was considered a simpler technique. The process of creating Marugame uchiwa fans is shown in detail from 0:16 in the video. Please enjoy the techniques of these Japanese artisans. Kagawa Prefecture's Marugame Uchiwa Fans as Souvenirs Source :YouTube screenshot These days, Japanese fans can be bought online, and they come in a variety of different designs and prices. There are cool traditional Japanese designs, cute flower patterns like morning-glory and Chinese bellflower, and artistic patterns that show off the craftsman's skills, making them a great gift for people who enjoy Japanese crafts and culture. Uchiwa no Minato Museum is located in Marugame, Kagawa prefecture, and is operated by the Kagawa Prefecture Fan Cooperative Association. It displays different kinds of Japanese fans such as Shibu Uchiwa (渋うちわ, Shibu-Uchiwa) and Ikkanbari, introduces the production process, and sells them as well. There's also a workshop where you can experience Japanese culture by creating an original and unique Japanese fan for yourself. Summary of Kagawa's Marugame Uchiwa Fans The Kagawa Prefecture Fan Cooperative Association has also started putting effort into training successors of the traditional craft. Marugame uchiwa fans have been certified as a traditional Japanese craft since 1997. At the peak of their popularity in 1955, 120 million fans were produced. In the video we're shown the production process, and you can come to understand the beauty and appeal of the traditional Marugame uchiwa fans that have been passed down for generations. 【Official Website】Uchiwa no Minato Museum https://marugameuchiwa.jp/facility 【Official Website】Aoyama Square https://kougeihin.jp/en/ -

Video article 7:58

Video article 7:58Edo-Kiriko – Works of Art That Shine Like Jewels. A Closer Look at the Charm of This Traditional Craft of Tokyo, Which Can Cost Millions of Yen or More, and How It's Made!

Traditional Crafts Things to Do- 653 plays

- YouTube

Edo Kiriko There are a variety of traditional crafts in Japanese culture, including "Edo Kiriko," a highly artistic piece of artwork that shines like a jewel. This is a video interview with an artisan of the traditional craft "Edo Kiriko," in which he talks about the process of making Edo Kiriko and the traditions of the craft. This article will briefly introduce Edo Kiriko alongside the video. Enjoy the beautiful art of Edo Kiriko, which has been handed down in Japan since ancient times. Edo Kiriko - A Compilation of Traditional Crafts Edo Kiriko, a traditional craft that has been handed down as part of traditional Japanese culture, is a historic traditional craft with beautiful jewel-like designs cut into glass. Edo Kiriko is said to have started in the late Edo Period (1750-1860 A.D.) when emery was used to engrave designs on the surface of glass. It gets its name from the cutting of the glass (切, pronounced "kiri," means cut in Japanese). Source :YouTube screenshot From the Taisho Era (1912-1926) to the early Showa period (around 1930), cut glass became popular, and a variety of products, such as tableware, became very popular. Now, prices vary from a few thousand yen to several tens of thousands of yen for the glass types and several millions of yen for jar types. Since each piece is hand crafted by an artisan, they are more expensive than regular glasses. Edo Kiriko is produced using Kagami crystal and soda lime glass. There are a very rich variety of patterns and colors used in the pieces. The video also includes an overview of the work in an Edo Kiriko workshop, and rare sketches can be seen at 3:10 in the video. The patterns show each artisan's sense of craftsmanship, and each artisan creates his or her own tasteful designs. The reason why many of the pieces are said to be high quality works of art is because of the skill of the artisans that create them. In the Edo period, the glassware was monochrome, but these days, they use glass with a colored surface layer. This is called "irogise" (color-dressing). Artisans design the colorful glasses while keeping in mind how they will look when drunk from. In the video, the Edo Kiriko artisan emphasizes that it's a traditional craft to be enjoyed by the eyes, which is why this part is so important. Although Edo Kiriko is an ancient Japanese culture, it is not a hereditary system; rather, it is passed down from generation to generation by apprentices who are serious about glass working. At 5:17 in the video, the artisan in the interview describes how he would like to continue to share his approach to Edo Kiriko with the next generation. Edo Kiriko - How It's Made Source :YouTube screenshot The following is a brief explanation of how Edo Kiriko is made. 1. Waridashi (Indexing) The glass is placed on a turntable and basic lines are drawn with a magic marker or similar writing instrument. This process is explained by the Edo Kiriko artisan at 3:10 in the video. 2. Arazuri (Rough Cutting) Making basic cuts that will be the basis for the pattern on the glass. 3. Sanbanzuri (Fine Cutting) Fine cuts are made into the glass. 4. Sokoishikake (Fine tuning of cuts) Smooth out the cuts so there are no irregularities. 5. Migaki (Polish) Polishing the glass to give it a nice shine. 6. Arai (Washing) Wash the glass. 7. Completed And it's finished! Edo Kiriko Makes a Great Gift, Souvenir, or Keepsake Photo:Edo Kiriko We highly recommended Edo Kiriko as a souvenir or gift. They can be purchased online and also at physical stores in Asakusa and Ginza, where you can see them up close and get a better look at their beauty. "Hanasho," with its main store in Kameido, and the "Sumida Edo Kiriko Museum" in Sumida, are famous for their shops, while the Edo Kiriko Cooperative in Kameido has a showroom where you can view various types of Edo Kiriko. Edo Kiriko includes glass cups, wine glasses, rock glasses, chilled sake cups, sake cups, sake glasses, sake bottles, lipped bowls, tumblers, beer glasses, and other items to suit your taste. Handmade Edo Kiriko would make a great gift for people of all ages. At the Edo Kiriko classes in Asakusa and Nihonbashi, you can experience the techniques of Edo Kiriko and draw patterns such as cherry blossoms and roses on glass. You can also learn the artisanal skills at the Edo Kiriko workshop and give a gift full of Japanese culture. At the Edo Kiriko Exhibition and the Edo Kiriko Museum, you can see many artisanal works of craft. If you want to see the craftsmanship in person, this is a great place to visit. You can also buy your favorite pieces as souvenirs. Like Edo Kiriko, "Satsuma-Kiriko" is another popular type of cut glass. These pieces are more suitable for ornamental purposes than Edo Kiriko. Summary of Edo Kiriko This article introduced the history of Edo Kiriko, a traditional craft in which Japanese craftsmanship truly shines. We recommend getting a pair of Edo Kiriko glasses that you can use for a variety of occassions. Due to the delicate nature of Edo Kiriko glass, they must be cared for more carefully than normal glasses. This video talks about the uncompromising dedication of Edo Kiriko artisans and the appeal of Edo Kiriko, which cannot be described in such a short amount of time. Please enjoy the video and learning about the depth of the ancient Japanese craft. -

Video article 4:04

Video article 4:04Chasen: Introducing the Characteristics and History of the Takayama Tea Whisk – A 500-Year-Old Utensil Essential for Traditional Japanese Tea Ceremony

Traditional Crafts History- 399 plays

- YouTube

Takayama Tea Whisks This video was made by Japanese Traditional Crafts Aoyama Square, a shop dedicated to Japanese traditional crafts, to introduce the Takayama Tea Whisk. Photo:Chasen (Tea Whisk) In the unique culture of Japanese tea ceremony, tea whisks are used for making matcha tea. Takayama Tea Whisks are traditional instruments made of bamboo and individually hand-crafted by artisans. In this article we'll introduce the charms and manufacturing process of Takayama Tea Whisks. Be sure to follow along with the video. Takayama Tea Whisks and Traditional Japanese Tea Ceremony Source :YouTube screenshot Japan has many traditional crafts with a long history. There is a wide variety of crafts including lacquerwares, ceramic wares, Buddhist altars, textiles, bamboo works, woodworks, Japanese paper, and many more. Tea ceremony utensils are traditional crafts that also have high cultural value as well. The tradition of tea drinking is said to have already started in the Heian period (794-1185 AD) in Japan. During the Kamakura period (1185 – 1333 AD), monk Eisai brought tea ceremony to Japan. As one of the most expensive tea whisks used for tea ceremony, the traditional Takayama Tea Whisk is made in Takayama in Ikoma City, Nara. The History and Cultural Value of Takayama Tea Whisks The production of Takayama Tea Whisks started around the middle of the Muromachi period (1336 – 1573 AD). The tea whisk was requested by Juko Murata, who started the tradition of Wabicha (a style of tea ceremony). Takayama Tamibe-no Jounyudo Souzetsu, the lord of Takayama’s son, accepted the request and made a special tea whisk for Murata. The tea whisk was presented to Emperor Gotsuchimikado and cherished by him. After the Edo period, the art of making Takayama Tea whisks had been handed down from artisans to only one of their children as a secret technique. In recent years however, the craftmanship has been passed down to 16 apprentices. The craft has been passed on as a handicraft of artisans in Takayama, Nara as well. The Characteristics and Manufacturing Process of Takayama Tea Whisks Source :YouTube screenshot Takayama Tea Whisks are made with many types of bamboo such as Henon bamboo, black bamboo and soot bamboo which is smoked in a hearth for many years. The edge of a bamboo pole is cracked into pieces, shaved thin, curled and fixed, then wrapped together to form a bamboo whisk. The painstakingly crafted Takayama Tea Whisks are truly works of art. Take a look at 0:29 in the video as it introduces the manufacturing process of Takayama Tea Whisks in detail. Summary of Takayama Tea Whisks The tradition of Japanese tea ceremony is also very popular outside Japan as it shows the Japanese spirit of Wabisabi. You can see that each tool made in the workshop is also a very profound traditional craft. We hope after reading this article and watching the video that we've sparked your interest in Takayama Tea Whisks. The maker of the video, Japan Traditional Crafts Aoyama Square, sells a variety of products including Takayama Tea Whisks. If you want to experience traditional Japanese culture or tea ceremony culture, we highly recommend that you purchase a traditional Takayama Tea Whisk. 【Official Website】Japan Traditional Crafts Aoyama Square https://kougeihin.jp/en/ -

Video article 1:32

Video article 1:32Arita Ware: A Traditional Japanese Craft of Arita, Saga That Was Coveted by European Royalty and Aristocracy in the 17th Century. Older Than Even the World-Famous Meissen!

Traditional Crafts Celebrities History- 256 plays

- YouTube

A Look at Arita Ware This is a promotional video for Japanese porcelain mainly produced in Arita, Saga Prefecture, produced by Japan Traditional Crafts Aoyama Square. If you are interested in learning how the traditional Japanese craft Arita ware is made or the history and culture of Arita Ware, this two-minute video is just what you're looking for! Here we'll introduce the culture and appeal Arita Ware, a traditional craft that is the pride of Japan. Nowadays, beautiful Japanese tableware is attracting a lot of attention from overseas, and many people visit Japan to create their own original tableware through pottery-making experiences such as Arita Ware. The History of Arita Ware Photo:Arita Ware coffee cup Arita ware refers to a type of Japanese porcelain produced in Arita, Saga and the area surrounding the town. Arita Ware is also known as Imari Ware and has over 400 years of the history as a traditional Japanese craft. It dates back 100 years before Meissen which is believed to have been the first place to produce porcelain in Europe. The start of Imari/Arita Ware was the discovery of pottery stones, the raw material used to make porcelain, in the Arita Izumiyama Magnet Field in Arita, Saga. Since no country in Europe was able to produce such white, thin, hard, and shiny porcelain in the 17th century, Arita Ware was popular among European nobles and began being exported to other countries in the late 17th century. Because the products were shipped from a port in Imari, Saga, Arita ware is also called Imari ware. The Characteristics of Arita Ware, a Traditional Japanese Craft and a Famous Important Cultural Property Arita porcelain is a thin, hard, pure white porcelain with a pure white base. The porcelain has shiny surfaces and makes a light metallic sound when tapped. It has a white background with a pattern called "etsuke," and is carefully hand-painted by a craftsman after being fired unglazed. The characteristics of etsuke reflect the culture of each period. One of the characteristics of Arita Ware is the various methods of expression depending on the method of painting and molding. The main variations are "hakuji" (white porcelain), "youkoku" (relief), "sometsuke" (blue and white), "iroe" (colored patterns), "seiji" (celadon), "ruriyu" (lapis lazuli), "sabiyu" (iron glaze) and "shinsha" (cinnabar). Every variation is as beautiful as the last. Arita ware is highly valued in Japan. For example, more than 10 works, including "Iroe Botan Shishi Mon Choushi" (a bottle with colored peony and lion patterns) and "Sometsuke Kaki Mon Tokkuri" (a bottle with blue and white flower patterns) are designated as Important Cultural Properties in Japan. The Traditional Way of Making Arita Ware Source :YouTube screenshot Arita ware is made through the following eight steps: quarrying, powdering, pugging, casting, terracotta, underglaze painting, glazing and baking. Therefore, many craftsmen work together to make a single piece of Arita Ware. Yukio Suzuta, the director of the Kyushu Ceramic Museum in Saga, said in the video: "Arita Ware is a division of labor, and there is a system in place to provide work to as many people as possible." The climate nurtures the culture, and through the hands of many artisans, a piece of art is born. Check out the video to see Arita Ware being made. Arita Ware Prices and Products Photo:Arita Ware pottery market Arita ware is highly valued as tableware for everyday use. Products such as paired bowls and mugs make great gifts as well. While expensive products cost more than a million yen, but there are also discounted teacups that are easily purchased for less than 1,000 yen (~$10 USD). Many Arita ware products are sold on online marketplaces such as Amazon and Rakuten, with the most popular products being coffee cups, mugs and Japanese teacups. Tourists visit the Arita Ceramics Fair, an annual festival held for Golden Week, to get Arita ware at reasonable prices. Summary of the Culture and Charms of Arita Ware While experiencing the history of Arita Ware, you can see the beautiful cityscape of Arita and the skills of the craftsmen who make the porcelain. Arita Ware is a traditional Japanese craft with a history older than the world-famous Meissen porcelain. In just two minutes, you can learn about the history, industry, characteristics, and craftsmanship of Arita Ware, so if you're interested in learning more, be sure to watch the video! Enjoy the world of traditional Arita Ware! 【Official Website】Japan Traditional Crafts Aoyama Square https://kougeihin.jp/en/ -

Video article 3:12

Video article 3:12Koshu Inden - A Beautiful Craft Using Lacquered Deer Leather. Discover Japanese Culture and Craftsmanship With These Amazing Artisans in Kofu, Yamanashi!

Traditional Crafts History- 267 plays

- YouTube

A Look at the Traditional Japanese Leather Crafted Goods of “Koshu Inden” This video, titled "koshu lacquered deerhide (手技TEWAZA「甲州印伝」)," produced by "Japanese Traditional Crafts Aoyoma Square," is a video that promotes "Koshu Inden," a traditional Japanese craft. Koshu Inden is a traditional craft that involves the lacquering of deer hide to create beautiful patters. The high quality leather craft goods made by these artisans has been loved through the ages. This video features how to make Koshu Inden. Enjoy the beauty of this traditional Japanese craft. Roots of Koshu Inden The history of Koshu Inden goes way back, and it was already being produced in the Nara period, about 1,300 years ago. Tabi (Japanese socks) made using the Inden technique are kept in the treasury of Shosoin (正倉院, Shosoin), and a box with an Inden inscription is also in the possession of Todaiji Temple (東大寺, Todaiji) in Nara Prefecture. Koshu Inden had been actively made in the castle town of Kofu-jo after the Edo period and pouches made using Koshu Inden techniques became popular among the common people. How Koshu Inden Are Made Source :YouTube screenshot Koshu inden is made through a series of processes such as tanning, dying, and lacquering animal hides such as deer or sheep. Koshu Inden is unique in that it is both soft to the touch and durable. Here we'll introduce the steps in Koshu Inden. 1. Yakizuri (0:29) The leather is scorched with an iron and then sanded. 2. Paper pattern (0:45) 3. Lacquering (1:01) The craftsman determines how the lacquers they choose will look. 4. Smoking (1:54) Color is put into the product through smoking. 5. Sewing (2:21) The work is shown in the video, making it very easy to understand. Recommended Items That Shine With Koshu Inden Craftsmanship Source :YouTube screenshot Inden-ya in Yamanashi Prefecture (山梨県: Yamanashi-ken) sells a lot of handmade goods made by Koshu Inden craftsmen. Yushichi Uehara, the founder of "Inden-ya" makes many soft-to-the-touch Koshu Inden goods by tanning deer hides using straw. Inden-ya's highly recommended products include Koshu Inden long wallets, coin purses, business card holders, inkan cases, Japanese pattern Kinchaku (drawstring purses), and more. The Sakura Komachi series, which features a motif of cherry blossoms in full bloom, is also very popular. You can see these products at 2:47 in the video. Recently products in collaboration with luxurious brands such as Gucci or Tiffany have caught the public's eye. These products are available at an online retailers such as Amazon or Rakuten. Summary of Koshu Inden Koshu Inden is a traditional Japanese craft as well as a highly fashionable product. As you can see from the video, you can use Koshu Inden goods for a long time thanks to the amazing handiwork of the Koshu Inden craftsmen. The Koshu Inden artisans in the video says, "The unique appeal of Koshu Inden is the large variety of patterns, with dozens of different colors in a single product, and the joy of being able to choose the color and pattern you like." 【Official Website】Japanese Traditional Crafts Aoyoma Square https://kougeihin.jp/en/ -

Video article 4:55

Video article 4:55The Beautiful Sound of the Koto: Hear the Entrancing Tones, Born of the Craftsmanship of Master Artisans

Traditional Crafts History- 1.06K plays

- YouTube

The Traditional Japanese Instrument: Koto We recommend this article to anyone interested in learning about traditional Japanese craftsmanship, or those who enjoy traditional Japanese instruments. In this article we’ll take a look at the "Koto," a traditional Japanese instrument that has been handed down for hundreds of years. The video “Introduction to the Manufacturing Process of the Koto" (琴の製造過程の紹介), produced by "Japanese Music Navi" (邦楽なび), features the manufacturing process of the Koto manufacturing company "Mitsuya Koto Corporation," in Saitama. The beautiful sound of the Koto is the result of age-old craftsmanship. This is a brief overview not only of how to make a Koto, but also about the history and style of the Koto. The production process of the Koto introduced in the video is so beautiful one cannot help be entranced by its beautiful chords. The BGM in the video is “Yaozoku bukyoku” performed on a Guzheng (another type of Chinese zither) made by the Mitsuya Koto Corporation. Be sure to listen closely as you watch the video. The History of the Koto Photo:Woman playing the koto The Koto is a traditional Japanese musical instrument. In the "Kojiki" (古事記, Records of Ancient Matters), there are scenes describing the playing of the Koto. In fact, remnants of what appears to be a koto have been found in Yayoi period ruins dating back to the 10th century BC. It is thought to have been used as a magical instrument at that time. Normally a koto has 13 strings but there was another type of Koto with 17 strings in the Edo Period. There are various types of Japanese stringed instruments, or "zithers": "Koto," “Sou," "Yamatogoto," "Ichigen goto" (a one stringed zither), "Nigen goto" (a two stringed zither), "Shichigen goto," (a seven stringed zither) and the "Nagoya harp." People often confuse the "Koto" and "So," but they are actually quite different. The biggest difference is that the Sou has a movable pole, called a "pillar," to adjust the pitch of the strings, while the Koto does not have a pillar, and the pitch is solely determined by where the strings are pressed. Other Traditional Japanese instruments besides the Koto include: Shakuhachi, Miyadaiko, Kodaiko, Naruko, Mokugyo, Sansen, Shamisen, Kokyu and the Biwa. The Type of Music Played on the Koto The music played on the Koto is called "Soukyoku" (筝曲, lit. "Koto Music." There are various music types such as the Tsukushi school, Yatsuhashi school, Ikuta school, the Yamada school, and more. Each school performs unique koto music. In terms of appearance, each school differs in posture and how the instrument in played. The shape of the instruments also differs from one school to the next. How a Koto Is Made Source :YouTube screenshot The manufacturing process of Kotos by the Mitsuya Koto Corporation consists of three main processes: "sawing," "instepping," and "wrapping," and the materials used are paulownia, red wood, rosewood, and silk threads. ・Sawing (0:08) The bark is stripped from trees one by one by hand. The length is then adjusted and it is marked. Next, they are cut into the shape of a koto and dried. Some are said to be dried for several years. ・Instepping (0:52) Using a number of special tools such as a planer and chisels, the insteps are carefully carved in detail. As you can see in the video, when the carving is finished, the instep is branded with the craftsman's name. After that, the surface of the Koto is baked evenly. The charred grain of the Koto looks beautiful. ・Wrapping (2:15) In this process, decorative accessories are created. These accessories are embedded into the Koto. ・ Completion (3:41) The beautiful wood grain and hand-embedded ornaments adorn the koto, making it look like a work of art. These masterpieces are a sight to behold. Summary of the Koto Photo:Koto This video features the detailed process of making the koto as well as the craftsmanship of the artisans. Take a moment to marvel at the craftsmanship. Kotos are available at online retailers such as Amazon or Rakuten. High quality goods are sold at the price of several million yen (thousands of dollars). If you are interested in the Koto, considering taking lessons or watching online courses. There are various lessons for both veterans and beginners. 【Official Website】Mitsuya Koto Corporation http://www.mitsuyakoto.com/ -

Video article 2:12

Video article 2:12Miyagi Prefecture's Traditional "Tokiwa Kongatazome" Hand Towels Attract People of All Ages! Don't Miss This Video About the Woman Carrying the Light of Tradition Into the Future!

Traditional Crafts- 186 plays

- Vimeo

The Traditional Japanese Art "Tokiwa Kongatazome" This video "Miyagi Prefecture, Tokiwa Kongatazome" ( 宮城県 常盤紺型染(ときわこんがたぞめ)), was created by "Tohoku STANDARD." The woman featured in the video is Kuniko Sasaki, a craftswoman who works at the Natoriya Dyeing Factory, a dye shop in Sendai City, Miyagi Prefecture in Japan's Tohoku region. The video is an interview where she speaks about how she encountered the traditional art and craft Tokiwa Kongatazome (常盤紺型染), as well as its origin and traditions. The Traditional Japanese Art and Craft "Tokiwa Kongatazome" Source :YouTube screenshot Tokiwa Kongatazome is a technique of stencil dyeing born in the late Edo period (1750 ~1850), and developed in Sendai City, Miyagi Prefecture. At that time, Tohoku did not have Kasuri-weaving (a textile technique in which patterns were woven using thread dyed in different colors), so people came up with the idea of creating a paper stencil based on the design patterns of Kasuri instead. It came to be called Tokiwa Kongatazome. The technique of Tokiwa Kongatazome was passed on from the dye shop "Mogamiya" (最上屋) in Akita prefecture to dye shops in Sendai city. People loved its warm fuzzy feeling and gorgeous patterns, and it made great strides from the Meiji era (1868~1912) to the early Showa era (1930~). One of its features is that it can be mass produced, unlike textiles. Tokiwa Kongatazome originated in Yokota city in Akita prefecture (Tohoku region) but developed in Sendai city in Miyagi prefecture. Source :YouTube screenshot The products dyed with the Tokiwa Kongatazome technique are called "Sendai Yukata" and are loved all over Japan. It initially only used deep blue colors for dyeing so it was named "Tokiwa 'Kon' gata" (Kon 紺, meaning "navy blue" in Japanese), but now it uses multiple colors so people sometimes call it somply "Tokiwagata" (without the kanji for navy blue). After World War II, Japanese fashion changed from Wafuku (Japanese-style) to Yofuku (Western-style), causing the Tokiwa Kongatazome technique to lose popularity. However, the dye shop "Natoriya Dyeing Factory" (名取屋染工場) uses Tokiwa Kongatazome in products like "Tenugui" (Hand towels), "Noren" (traditional Japanese fabric dividers hung on/between walls), flags, curtains, banners, "Hanten" (short, Japanese-style winter coats), and other small items. How It's Made: Tokiwa Kongatazome Stencil Dyeing Source :YouTube screenshot As it shows in the video around 0:41, first you put a Tokiwa Kongatazome stencil on a white fabric and apply starch. The starched area is going to be left white after the fabric is dyed, forming a pattern on the cloth. An example of this stencil dyeing is shown in the video around 1:49. A technique called "Itoire" (Inserting threads into a paper-stencil) is used to create a paper-stencil. This technique allows for the design of more intricate patterns. As you can tell by watching the video, everything is handcrafted by professionals. Summary of Tokiwa Kongatazome Source :YouTube screenshot Kuniko Sasaki of the "Natoriya Dyeing Factory" says in the interview that she started Tokiwa Kongatazome because she found stencils that were more than 100 years old when she was cleaning out her warehouse roughly 20 years ago, and she thought it would be a shame to lose the traditional craft. Feeling this, she decided she wanted to pass on the spirit of the craftsmen before her. Tokiwa Kongatazome products are also available online. The popular hand towels are available for purchase for around 1,000 yen (~$10 USD). Tokiwa Kongatazome is also popular among younger people and foreigners. Enjoy watching the video and get to know Tokiwa Kongatazome! -

Video article 3:52

Video article 3:52The Beauty of the Traditional Japanese Dyeing Technique "Chusen." Enjoy the Priceless Footage of These Hand-Crafted Works

Traditional Crafts- 178 plays

- YouTube

The PR Video for "Chusen," a Traditional Japanese Dyeing Technique This video, titled "Chusen - Hand-dyeing technique (Japan)," produced by "IKIDANE NIPPON" features one of Japan's traditional dyeing techniques. "Chusen" is a traditional dyeing technique that originated in Sakai (堺市:Sakai-shi), Osaka in the early Edo Period. Chusen is also called "Sosogi-zome." Dyed textiles are used not only for rolls of cloth and clothing like Yukata, and Jinbei, but also for commonly used items like dish cloths or handkerchiefs. This video clip features the traditional dyeing technique Chusen. We hope you enjoy this rare footage! The Chusen Dyeing Technique Source :YouTube screenshot Chusen is a traditional dyeing technique whereby you dye each piece one by one, and requires highly skilled craftsmen to create perfect, even dyeing. First, place the material cloth on the board and apply anti-dye adhesive to the non-dyeing areas using patterned paper. (0:05). After the pastes are dried, set a frame to an area to be dyed (1:08) and pour the dye compounds onto the cloth. If cloths are dyed twice, in a distinct way, by layering them on top of each other by the bellows, a beautiful color will be produced, and the back side will have a vivid appearance. Dyed textures are washed with water and dried. You can see the completed product in the footage from 3:04. Chusen uses the same technique to dye yarns, therefore, it does not lose its elasticity and breath-ability. Let's Use Chusen Dyed Products Source :YouTube screenshot As you can see from this video clip, these traditional dyed products are made by hand, one by one. These Chusen products, with an air of Japanese culture, are very popular as souvenirs. Chusen products are available on online shopping sites. In recent years, MUJI has introduced a new line of chusen items that have attracted a lot of attention. If properly cared for, Chusen products will change into a beautiful color and can be used for a long time. We also recommend trying a Chusen experience class to see what Chusen dyeing is like. Summary of Chusen, the Traditional Hand Dyeing Technique Source :YouTube screenshot The footage from 3:11 features various Chusen products. Chusen has many different types of patterns such as such as small crests, stripes, chidori patterns, and floral patterns. There are also various techniques, such as using multiple dyeing compounds to make colors brighter, or discharge dyeing to make colors dark. There is another traditional dyeing method in Japan besides Chusen; it is called "Nattsen." Definitely check out some chusen products if you have the chance! 【Official Website】Tenukuri kobo |Tokyo Wasarasi Sozokan https://souzou-kan.info/en/ -

Video article 22:01

Video article 22:01The Techniques of a Master Swordsmith! A Young Man Who Inherited the Long History of Echizen Cutlery!

Traditional Crafts- 112 plays

- YouTube

越前打刃物の起源と歴史 こちらの動画は「明日への扉 by アットホーム」が公開した「#070 越前打刃物職人 田村 徹 | 明日への扉 by アットホーム」です。 日本の福井県越前市には昔より刀剣を製造していた歴史があり、その技術が越前打刃物という伝統文化工芸に生かされています。 打刃物とは鉄を打って作る刃物のことで、1337年に千代鶴国安によって作られたとされています。 千代鶴神社にその文献が残され、以降700年もの長い間、職人の手によって受け継がれました。 越前打刃物は1979年には国の伝統工芸品として認定されます。 越前打刃物とは産地福井県越前市において700年の歴史と伝統がある刃物です。 型を抜いて作るのでなく、熱した鉄を打つことで一つの作品を製造するという特徴があります。 日本の伝統文化工芸を受け継ぐ若き越前打刃物職人・田村徹 そんな伝統文化工芸である越前打刃物の職人として修行し若き力を注いでいるのが、動画紹介されている田村徹さんです。 田村徹さんが現在師事しているのが、黄綬褒章も受賞した偉大なる師・清水正治さんです。 日本の伝統文化工芸を守る名工清水さんの最も有名な刃物が鮪包丁です。 刃渡り100センチ以上にもなる包丁を作れるのは日本でも数えるほどしかおらず、その匠の技と技法は唯一無二で伝統文化そのものと言えます。 清水正治さんの手仕事はメディアはもちろんのこと、多くの知識人からも支持されており清水正治さんの打刃物でなければならないと語る職人も多くいます。 日本の伝統文化工芸越前打刃物に挑む若き職人 弟子である田村徹さんが今回の動画の中で製作しているのは出刃包丁です。 その材料となるのは地金と鋼です。 包丁の種類は大きく分けて両刃と片刃という種類に分けられ、その用途によって研ぎ方を変えています。 動画の中では6:30より解説されています。 まずは工房の高温の炉のなかで柄に差し込む部分を作る中子取りという作業を行います。 その後、焼入れという工程で800度の窯から一気に冷水で冷やします。 柿色と言われる色合いまで加熱を行うとても繊細な作業です。 そして研師によって刃付け(研ぎ)という作業を行います。 完成した包丁は、もはや芸術品・美術品の一つとしても過言ではないほどの美しさと精巧さを備えたものとなります。 日本伝統文化である越前打刃物は包丁などの調理用品だけでなく、鎌など農業や林業、園芸にも用いられています。 日本伝統文化工芸越前打刃物紹介まとめ 越前打刃物という歴史ある日本伝統工芸作品を今まで以上に身近に感じることができたでしょうか。 毎日使用する包丁だからこそ、日本伝統文化である越前打刃物に触れてみてはいかがでしょうか。 -

Video article 11:05

Video article 11:05Swords Forged by Japanese Craftsmen Are Truly Works of Art! Don't Take Your Eyes off This Artisanship!

Traditional Crafts- 467 plays

- YouTube

1000年以上も続く伝統文化「刀鍛冶」 こちらの動画は「redbowkk9600」が公開した、兵庫県篠山市で日本刀の制作している藤井啓介さんが日本刀を鍛錬する様子を収めた「日本刀鍛錬 katana making(1)」だ。 古くは約1000年前の平安時代から使われてきた日本固有の武器「日本刀」。 世界的にも有名なこの武器は、切ることに特化しており、その性能は他の武器の追随を許さないほどだ。 現代の平和な日本において日本刀が武器として使われることはない。 しかし日本刀には、武器としての性能以上に伝統工芸品としての美しさがある。 刀鍛冶の職人が作った日本刀は、まさに芸術品だ。 伝統工芸品である日本刀を作る職人(刀匠)は、減少傾向にある。 これは日本刀自体が高価で需要が少ないこともあるが、刀鍛冶としての技術を継承することが非常に難しいことが主な原因だ。 刀鍛冶になり、日本伝統の継承者になろうと思っても最低5年の修行期間を経て、やっと本格的な日本刀の鍛錬ができるようになる。 鋭い切れ味と強靱な刀身を実現する日本刀の原料とは? 日本刀が他の刃物と大きく違う点は原材料にある。 伝統工芸品である日本刀は「玉鋼(たまはがね)」と呼ばれる良質な鋼でできている。 この「玉鋼」は現在は日本刀の原材料でしか使われておらず、「たたら製鉄」という特有の製鉄法で製錬される。 「玉鋼」は普通の鋼と比較すると不純物が少ないので非常に美しくあり、また加工しやすく割れにくいという特徴がある。 「玉鋼」はまさに、日本刀のために製錬された鉱物なのだ。 また日本の歴史の中で太刀や短刀などさまざまな刀長の種類の日本刀が作られたが、いずれも「玉鋼」を原料にしたものが重宝されてきた。 匠の技による日本刀の意外な作刀法 日本刀が伝統工芸品として高価で取引されている理由は、一振り一振りが職人の手によって鍛錬されているからだ。 日本刀の鍛錬は機械では真似できず、職人が受け継いできた技術により丁寧に鍛錬していくしかない。 一振りの日本刀を鍛錬し完成させるためには約2週間かかる。 日本刀の鍛錬は鋼を高温で熱し、細長い形にするという単純な作り方ではない。 日本刀の鍛錬の特徴は、高温に熱し加工しやすくした「玉鋼」を何度も折り返し重ねることだ。この折り返しは10回から12回繰り返す。 この手間のかかる工程と技法を行うことで、不純物の少ない「玉鋼」からさらに不純物を取り除くことができ、さらに日本刀の仕上がりも丈夫なものができる。 「刀鍛冶」紹介まとめ 日本刀は日本の伝統工芸品の中でも非常に歴史が深く、美術品として誰もが認める美しさをもっている。 現在では日本刀の鍛錬の様子を見学させてもらえる鍛冶場も多く存在する。間近で職人が刀を鍛錬する様子はまさに圧巻だ。 また、伝統工芸作品として登録された日本刀はだれでも購入することができる。 美術品として気になる方は、専門店に行くとさまざまな日本刀を見ることができるのでオススメだ。 -

Video article 3:15

Video article 3:15Edo Woodblock Printing Was Created by Katsushika Hokusai and Others Who Had a Great Influence on the Art of the World. The Works Created With This Tradition Have Attracted People From All Over the World!

Traditional Crafts- 96 plays

- YouTube

江戸木版画紹介動画について こちらの動画は「伝統工芸 青山スクエア」が公開した「手技TEWAZA「江戸木版画」EDO MOKUHANGA Woodblock Prints/伝統工芸 青山スクエア Japan traditional crafts Aoyama Square」です。 日本を代表する伝統工芸品の一つがこの動画で紹介されている「江戸木版画」です。 浮世絵は直接布や紙に筆で描かれる事もありますが、有名な作品には木版画が多いのです。 代表的な江戸木版画の作家は葛飾北斎、喜多川歌麿、歌川広重、東洲斎写楽など、いずれも世界の芸術や文化に多大なる影響を与えた偉大な日本のアーティストたちです。 江戸木版画とは 江戸木版画は400年以上の歴史をもつ伝統工芸です。 そしてその名の通り「江戸」で発展した技法です。 江戸時代といえば日本の歴史の中で最も天下泰平が長かった時代と言われています。 平和な世の中で文化や芸術が大きく花開きました。 江戸の町では人気の歌舞伎役者や芝居小屋の役者さんのポスターやブロマイドは飛ぶように売れていたと伝えられています。 そう、このブロマイドやポスターというのが江戸木版画で刷られた浮世絵です。 まだ印刷技術が未発達だった時代に木版画は絵や本を大量生産できる革新的な印刷方法でした。 これは文化的な革命といっても過言ではありません。 このように江戸木版画は江戸時代の重要な産業の一つだったのです。 江戸木版画の歴史 写楽や北斎は当時から絶大な人気のあった絵師ですが、版画浮世絵というのは彼らが一人で作成したわけではありません。 江戸木版画は分業制で、絵師が描いた下絵を元に彫師が木の板に掘り、摺師が一枚の版画絵に仕上げていくのが特徴です。 ともすれば絵師の名前だけが有名になりがちですが、作品の出来を左右するのは彫師と摺師(すりし)の腕だと言われています。 指定された色やパーツごとに彫師が彫刻刀や短刀などの道具で版木を作り、摺師はそれを何度もすり上げてあの繊細な細工が施された芸術作品が生み出されるのです。 江戸木版画紹介まとめ 江戸木版画という文化は日本の伝統工芸の一つですが、現在でもその流れは途切れていません。 こちらの動画で紹介した「高橋工房」さんでは伝統工芸士に指定された絵師、彫師、摺師が後継者の育成を行っています。 また、常設しているギャラリーでは日本が世界に誇る伝統工芸、江戸木版画の魅力をあますところなく体験することができます。 さらに、高橋工房さんでは名所江戸百景や富嶽三十六景など誰もが知るあの名画の復刻版の販売を行っています。 動画にも登場してきた熟練の彫師さんが丹精込めて掘った版木(素材は山桜)を使い、人間国宝の手によって漉かれた和紙へ摺師が魂を込めて刷った最高級の浮世絵名画の数々を、その目と手で実感してみてはいかがでしょうか? -

Video article 4:51

Video article 4:51Fusuma and Folding Screens Affixed With "Edo Karakami" to Become Works of Art! This Historic Craft, Which Was Used to Write Waka Poetry in the Heian Period, Is Filled With the Japanese Spirit of "Wa"

Traditional Crafts- 275 plays

- YouTube